How to Optimize Additive Manufacturing Designs

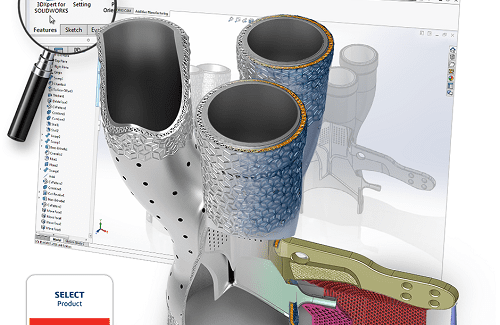

3DXpert for SolidWorks from 3D Systems is an integrated system that gives designers a direct path for preparing and optimizing their SolidWorks designs for both plastic and metal additive manufacturing, creating the design freedom to produce complex geometries, lightweight parts without compromising strength, and apply surface texture to deliver functional or aesthetic benefits.

Posted: February 22, 2018

Capitalizing on the rapid advancement of additive manufacturing – which many analysts estimate will top $20 billion in revenue by 2020 – fabricators are now shifting from rapid prototyping to mainstream production. Within the AM environment, complex structures can easily become a reality for rapid product development, reduced time to market, and lower total cost of operation. But despite this rapid growth, many designers are not fully exploiting AM capabilities because the way to get there is either not accessible or too difficult to navigate. To effectively design for additive manufacturing, designers must shift their mindset from what they know of traditional manufacturing processes and employ the right design tools, making design an integral part of the manufacturing workflow. To accomplish this, 3D Systems, Inc. (Rock Hill, SC) offers 3DXpert™ for SolidWorks, an integrated system that streamlines preparation and optimization stages from design to manufacturing.

This software provides a distinct and exclusive advantage to SolidWorks users by enabling them to prepare and optimize designs for both plastic and metal additive manufacturing. It combines a new layer of AM tools that designers need from 3DXpert with the familiar CAD environment of SolidWorks from Dassault Systèmes (Vélizy-Villacoublay, France) so that they have the design freedom to produce complex geometries, lightweight parts without compromising strength, and apply surface texture to deliver functional or aesthetic benefits. Designers using 3DXpert for SolidWorks can:

- Maintain design integrity by working with native CAD solids without converting them into STL, or toggling between several software programs to accomplish all tasks.

- Optimize structures with rapid creation of lattice-based structures for lightweighting and applying surface textures.

- Ensure quality printed parts by using real-time analysis for best-fit positioning and orientation of the part. Use of automated analysis and setting of support structures helps designers ensure surface quality and prevents part distortion.

- Accelerate preparation time by employing automatic features such as tray setup, and estimation of material usage and build time.

“We are excited to partner with Dassault and help users experience the reality of 3D printing through this new software,” said Vyomesh Joshi, the president and chief executive officer of 3D Systems. “This collaboration enables SolidWorks users to create more shapes, more ways, and accelerate product development cycles while lowering costs. We are offering designers a true competitive advantage while re-defining the design and manufacturing process. By providing a direct path from SolidWorks users’ designs to additive manufacturing, they become more competitive and expand the types of projects they can design.”

“We’ve seen a tremendous increase in the adoption of additive manufacturing,” said Gian Paolo Bassi, the chief executive officer of SolidWorks, Dassault Systèmes. “As a result, we collaborated with them to provide our users with tools to help them design specifically for additive manufacturing – which requires a different set of operations and rules than more traditional, subtractive manufacturing. Available with all of our 3D CAD subscriptions, 3DXpert for SolidWorks allows designers to be able to optimize their design for additive manufacturing, check for manufacturability without any waste of time and material, and attain a competitive advantage in the market.” Available exclusively to SolidWorks customers and included in their annual subscription, the standard edition of 3DXpert for SolidWorks is now available via download. Additional add-ons with advanced lattice design, lattice optimization tools, and a new 3DXpert for SolidWorks Professional edition are available through SolidWorks’ VAR network.

3D Systems, Inc., 333 Three D Systems Circle, Rock Hill, SC 29730, 803-326-3900, www.3dsystems.com.