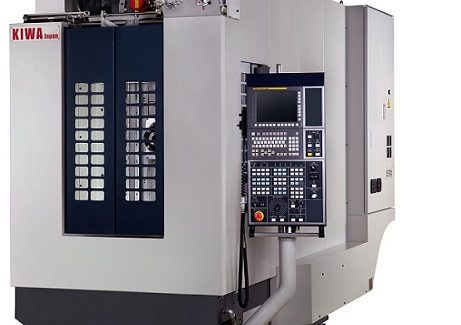

Innovative, Compact HMC With Column Traverse Structure

The KIWA-Japan Triple H40 Horizontal Machining Center with a Column Traverse Structure from Methods Machine Tools supports the flexible mounting of various fixtures and rotary tables based on the application.

Posted: February 15, 2018

One of the most unique design features of the KIWA-Japan Triple H40 Horizontal Machining Center with a Column Traverse Structure from Methods Machine Tools, Inc. (Sudbury, MA) is its ability to support flexible mounting of various fixtures and rotary tables based on the application. The stationary table design enables long workpieces to be clamped firmly to the table, eliminating the back and forth action of moving parts with special guarding and allowing machining access to either ends of long workpieces. The KIWA Triple H40 has a very compact machining area of 43.3 in (1,100 mm) x 23.6 in (600 mm) x 31.5 in (800 mm). The work table stays stationary and the X/Y/Z axis ball screws and roller guides are behind the X/Y axis way covers. The Z-axis moves back and forth on the column, which assures higher rigidity of the spindle than quill type spindles. In addition, the long-nosed spindle has six bearings for increased stability.

Pallet size is 32.3 in (820 mm) x 17.7 in (450 mm) with a maximum work height of 31.1 in (790 mm) and a maximum workload of 2,200 lb (1,000 kg). Exceptionally efficient chip evacuation is possible as a result of the minimized machining area due to the moving column structure and a large opening in the bed. The Triple H40 also features a new armless Automatic Tool Changer (ATC) mounted on the top of the machine to save space, which allows the spindle to directly change tools with the magazine, eliminating the need for a tool change arm. This is available in a 20-tool or 40-tool system. “The Triple H40 is perfect for larger fixturing and supports good access for automation,” said Bernie Otto, the KIWA product manager for Methods Machine Tools. “This machine is also ideal for parts that are long and need work done on the ends.”

Methods Machine Tools, Inc., 65 Union Avenue, Sudbury, MA 01776, 978-443-5388, Fax: 978-440-9405, www.methodsmachine.com.