Portable All-Electric Press Brake for Versatile Forming of Basic and Complex Shapes

The versatile all-electric GOFORM 40 ton press brake from Cincinnati Incorporated is perfect for small parts up to 0.25 in thick and less than 50 lb, but also has a 10 in stroke and 17 in open height for jobs requiring tall tools and adapters.

Posted: February 12, 2018

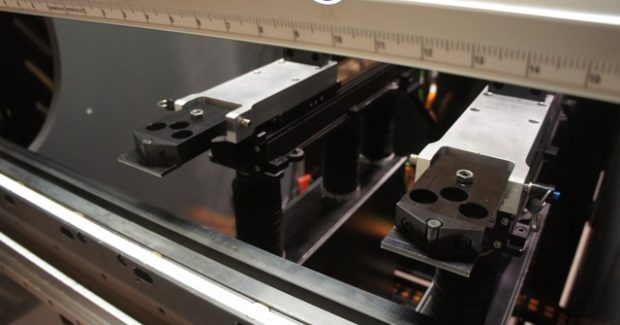

Cincinnati Incorporated (CI; Harrison, OH) offers their versatile all-electric GOFORM 40 ton press brake that is perfect for small parts up to 0.25 in thick and less than 50 lb, but also has a 10 in stroke and 17 in open height for jobs requiring tall tools and adapters. Its six-axis backgauge is ideal for basic and complex part shapes. This press brake has a heavy duty, stress-relieved frame that is ready for multi-shift operation and is designed for full tonnage with minimal deflection. The drive system uses satellite roller screw actuators that reduce heat and wear for a long life of heavy use. “We designed this system to pack a punch in a small package,” said Todd Kirchoff, a product manager for machine tool products at Cincinnati Incorporated. “The machine has a small footprint, can be easily moved with a forklift or overhead crane, and operates without being anchored to the floor, so it can adapt to changing plant layouts and workflows.”

GOFORM can be configured to use three major tooling styles – American, WT/New Standard and European – and Express Clamp systems from Wilson Tool (White Bear Lake, MN) that provide fast setup, self-seating and low maintenance with leak-free mechanical clamps. The Express Die Holder uses a full length clamp rather than multiple set screws, allowing segmented dies to be used anywhere along the length of the bed. The European 1V and 2V die holders can be used directly on the bed, without filler blocks. The press brake uses high resolution incremental encoders to ensure exceptional ram repeatability for accurate small-part forming. The PC-based control allows operators to setup jobs quickly with consistent results, and pre-loaded tool files help simplify programming and improve first-bend accuracy. Programs can be created on the control or offline with the Bend Simulation Module.

https://youtu.be/FbhtFhwmT0E

Cincinnati Incorporated, 7420 Kilby Road, Harrison, OH 45030, 513-367-7100, info@e-ci.com, www.e-ci.com.