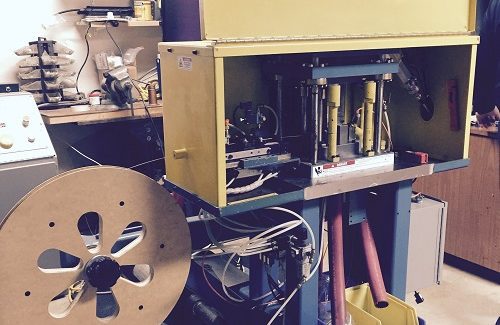

Press System with In-Die Laser Welding Eliminates Time-Intensive Labor

The laser welding, parts assembly and cut-off operations inside the pneumatic stamping press system with in-die laser welding capability from Airam eliminate time-intensive labor, improve repeatability and reduce material handling without sacrificing production speed.

Posted: February 12, 2018

Airam Press Company Ltd. (Covington, OH) has introduced a pneumatic stamping press system with in-die laser welding capability to help fabricators eliminate time-intensive labor, improve repeatability and reduce material handling. Laser welding, parts assembly and cut-off operations take place inside the press without sacrificing production speed. A multi-level, multi-station die can be designed to accommodate user requirements, along with a PLC control and feedlines. “We integrated the laser with the press and designed a press enclosure that meets current safety standards, but also gives the operator easy access,” says John Bornhorst, the vice president of engineering for Airam. “Once the stamping operation is completed, the press precisely locates, positions and holds the part in place for laser welding and cut-off. Fabricators can stamp and weld different types of materials together as well, so the applications are endless.”

This robust production system is maintenance-free and economical to operate. Press designs can also be tailored to user requirements at a lower cost by starting with established technology that includes an uptime rating of 98 percent. Full tonnage is available through the entire stroke, which can be controlled to form material as quickly or as slowly as an application requires. Programming takes the guesswork out of systems like the pneumatic press with in-die laser welding, allowing fabricators to quickly train operators with less experience.

Airam Press Company Ltd., 2065 Industrial Court, PO Box 9, Covington, OH 45318, 800-842-4726, sales@airam.com, www.airam.com.