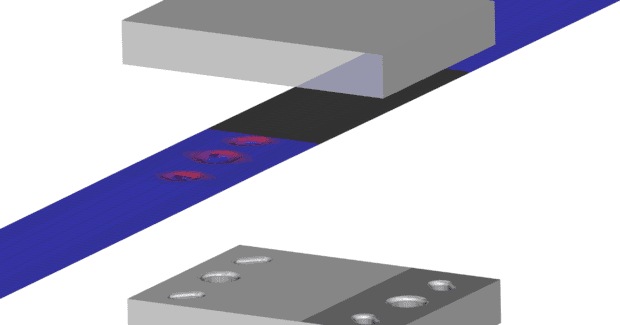

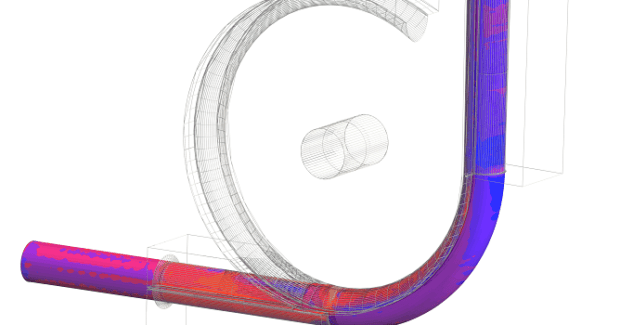

Simulation of Tube Embossing and Bending for Roll Formers

Roll forming procedures, pre- and post-processing steps can be optimally calculated to improve the forming process as a whole using COPRA FEA RF software from data M, which visualizes and verifies the production process within a virtual environment to prevent deviations during production.

Posted: February 22, 2018

Tube and pipe fabrication demands precisely fitting and complex parts with small bending radius to wall thickness ratios that is ever more demanding. The COPRA® FEA RF software system from data M Sheet Metal Solutions GmbH (Valley, Bavaria, Germany) visualizes and verifies the production process within a virtual environment to prevent deviations during production. By taking into account previous roll forming procedures, pre- and post-processing steps can be optimally calculated to improve the forming process as a whole. The company provides extensive service and training packages for COPRA FEA RF that contain complete model examples, including video tutorials for the integration of pre- and post-processing operations with a focus on embossing and tube bending. As designers learn how to utilize the advanced functionalities of the system using these training packages for the software, they are able to integrate additional processing steps into the forming operations of their roll formers.

Detailed instructions for the application of COPRA FEA RF enable roll formers to create better models for future projects. Special trainings can also be conducted upon request. These packages contain a ready-to-use simulation model, as well as 3D models for any necessary tools that can be used immediately with the 3D import functions of COPRA FEA RF. A manual for creating example models, including a video tutorial, is also part of the portfolio.

Data M Sheet Metal Solutions GmbH, Am Marschallfeld 17 83626 Valley, Germany, +49 (0) 8024-640-0 Fax: +49 (0) 8024-640-300, datam@datam.de, www.datam.de.