Single Operator, Semi-Automated, and Fully Automated Resistance Welding, Laser Welding and More

The 24-page color Integrated Systems Brochure from Amada Miyachi America details their in-house system design and manufacturing capabilities of resistance welding and laser welding systems, as well as marking, cutting, and micro machining equipment and systems.

Posted: February 27, 2018

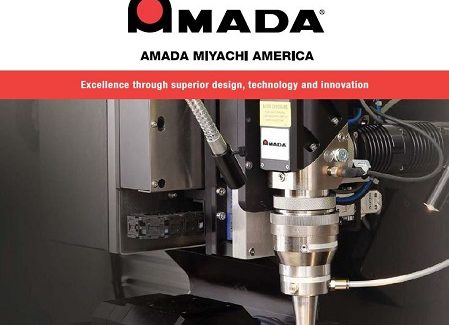

The Integrated Systems Brochure from Amada Miyachi America, Inc. (Monrovia, CA), details their in-house system design and manufacturing capabilities of resistance welding and laser welding systems, as well as marking, cutting, and micro machining equipment and systems. Described in this 24-page color brochure are integrated systems for laser welding, laser cutting, laser marking, micromachining, resistance welding, and seam sealing, as well as gloveboxes, and reflow soldering and bonding. Featuring clear, high resolution pictures of system components and options, the brochure also incorporates a range of photos illustrating typical applications for which each system is utilized. Integrated system components highlighted in the brochure include safety enclosures, multi-axis motion, laser and resistance processing, custom tooling, and system or process monitoring. Also included are conveyor systems, robotic and other material handling options, vision, and custom software development. Single operator, semi-automated, and fully automated integrated systems are available.

Amada Miyachi America has an installed base of more than 1,000 standard and custom integrated systems, and maintains a large team of dedicated system engineers and system assemblers, along with mechanical, electrical and software engineers, all devoted to integrating the correct system components for a specific application. Developed following a customer journey along their industry-leading Define – Design – Deliver path, each system is tailored to customer requirements of production throughput, product flow, and quality based on specific application results. With a dedicated project manager assigned to every system, clear acceptance criteria is developed for each project. The process includes concept 3D renderings, project timelines with major milestones, and detailed compliance response documents.

Amada Miyachi America, Inc., 1820 South Myrtle Avenue, Monrovia, CA 91016, 626-303-5676, info@amadamiyachi.com, www.amadamiyachi.com.