Next Steps in Double Layer Body Building

Take a look at how Alfa Romeo uses the innovative and flexible OpenGate framing system from Comau for impressive high speed construction of their luxury Giulia automobile.

Posted: February 14, 2018

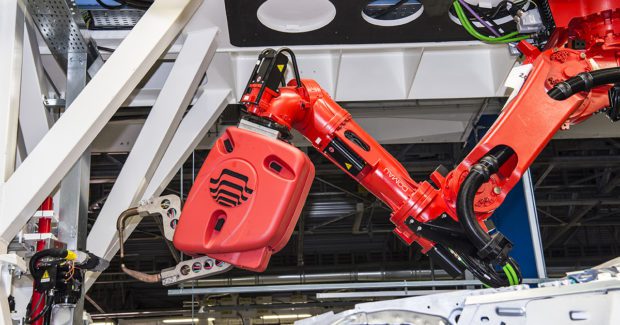

Leveraging articulated robots and flexible framing stations that handle advanced lightweight materials, Alfa Romeo Automobiles SpA (Turin, Italy) builds the luxury Giulia automobile in their Cassino plant using a modular, flexible and expandable OpenGate framing system from Comau SpA (Grugliasco, Italy) that guarantees high repeatability and can handle up to four different models for maximum flexibility and return on investment. The compact and lean architecture of this system features up to 18 overhead-mounted robots and up to six dedicated model gates that deliver high speed, high density operations for automated assembly that meets the production targets of the Giulia. This set-up also uses parts of the modular ComauFlex system, including the VersaRoll closed loop assembly and joining system that is primarily used for setting the geometry of the body sides and the chassis to assure fast transfer of material through the line and reduce non-value added time.

Both the OpenGate and VersaRoll systems utilize overhead-mounted robots, allowing the highest possible density of robots and increasing the volume of joining operations within each station. The first section of the line is where the chassis is built, consisting of the front framework (where the engine and all the related mechanical components are mounted), the central floor (including the first row of seats) and the back framework (the second row of seats). Once the automatic cycle starts, each chassis is processed in sequence by various industrial robots. Once completed, the chassis moves into the section where the body is added. Here a total of two OpenGate framing stations work sequentially in a unique configuration that performs the delicate operation in a “double layer” construction process of the body, which is essentially broken down and assembled in two specific steps: In the first station, the structural or internal part of the chassis and its sides are built, while in the subsequent phase, the so-called ‘outer skin’ is added.

This advanced process greatly improves accessibility and helps facilitate the work of the robots as they weld, position the various elements and perform other activities that are needed to complete the assembly. Because the robots have complete, unobstructed access to the structural “skeleton” of the vehicle, welding operations are more effective and more precise than in a traditional process, which leads to better overall manufacturing geometry. At the same time, in a separate station, the external part of the vehicle is prepared, positioned and fastened to the structural skeleton.

The extensive use of lightweight materials, such as aluminum that is inherently more delicate than its traditional steel-based counterparts, requires great precision and accuracy during the joining and finishing processes. Since the Giulia Quadrifoglio model is fitted with a carbon-fiber roof and hood, process complexity is further increased. Unlike the other models, where the aluminum roof is fastened via laser brazing, the carbon-fiber roof of the Quadrifoglio is prepared and assembled within a 100 percent automated workstation. The patent-pending process consists of multiple robots that are aided by advanced vision and control systems to secure the highest possible standards. This entire process is controlled for quality and precision: from the automatic cleaning of the components, to the mixing, distributing and spreading the bicomponent glue, all the way to its polymerization, which features an innovative InfraRed System that is followed by a subsequent testing of the 100 percent watertight seal.

Another manufacturing innovation is the RHEvo roller hemming system that combines performance and efficiency with real-time data collection and process monitoring. With speeds of up to 750 mm/s, RHEvo can hem very complex elements across multiple manufacturing lines while protecting the geometric uniformity of the assembled parts, reducing time-to-market and lowering overall production costs. RHEvo is used to hem the rear wheelarch on the Giulia models, helping safeguard the rigid torque that these high performance sports sedans require.

Advanced vision systems are used here to identify and correct any positioning variables introduced when the chassis is placed within the station. The vision system not only calculates the exact position of the wheelarch, it also sends the data to the robot in order to correctly position the anvil in respect to the wheelarch. Working together, the robot can then recalibrate its position such that it is perfectly centered in respect to the wheelarch. RHEvo, working in a pull mode, then automatically hems the wheelarch, creating a perfectly precise drop hem in three passages and using two types of rollers. Once the hemming process is complete, the system automatically reconfigures itself for the next model. This advanced system is flexible enough to manage up to four different models without the need for additional set-up or operator intervention.

Comau LLC, 2800 West 14 Mile Road, Royal Oak, MI 48073, 248-353-8888, www.comau.com.