Welding Helmet with Lens Technology for Multiple Welding Jobs in Power Generation Work

The VIKING PAPR 3350 Welding Helmet from Lincoln Electric has an optional extended battery pack and 4C lens technology that gives operators a clear and undistorted view of the welding arc and puddle to maximize control and minimize defects.

Posted: February 14, 2018

The updated VIKING™ PAPR 3350 Welding Helmet from Lincoln Electric (Cleveland, OH) now has 4C® lens technology and an optional extended battery pack that is ideal for multiple welding processes in the power generation applications. This 4C lens technology upgrade improves the optics and reduces eye strain by minimizing the lime-green coloring in the liquid crystal display (LCD) in both active and inactive states. The technology gives operators the ability to see a clear and undistorted view of the welding arc and puddle to maximize control and minimize defects. The 4C stands for the following attributes:

- Clarity – Optical clarity at the highest EN379 1/1/1/1 levels

- Color – Real color view

- Carat – Lightweight auto-darkening filter

- Cut – Even shade from any angle

In addition to the updated lens technology, an extended battery pack is offered for the system: a rechargeable lithium ion battery provides up to 16 hours of battery life at the low air flow setting and is rated for 500+ charges. While the standard battery provides up to nine hours of battery life, the extended battery pack provides more flexibility when working overtime and acts as a safeguard when the system has not been charged. The extended battery pack is NIOSH-approved (National Institute for Occupational Safety and Health) and weighs just one pound. The PAPR (Powered Air Purifying Respirator) is a complete powered system that draws air from the environment through a HEPA filter located on the belt and delivers filtered air in the breathing zone within a premium-level VIKING auto-darkening welding helmet. A patent-pending adjustable baffling system inside the helmet directs airflow away from the eyes to avoid dryness.

For heavy fabrication and general fabrication, the Power Wave® R450 robotic power source brings the latest high performance robotic welding system to the manufacturing floor for increased productivity, quality and cost savings. As one of the most capable 450A robotic power sources, the Power Wave R450 is equipped with Waveform Control Technology® for the most comprehensive portfolio of welding modes, including MIG, TIG, flux core, and advanced pulse modes specific for nickel, stainless, and low- and high-alloy steel as thin as 0.6 mm. Rated for 450A at 100 percent duty cycle, this power source delivers the industry’s fastest travel speeds, lowest spatter generation, and best gap bridging capability. Engineered with ArcLink®, the world’s fastest robotic communications interface, the Power Wave R450 provides simple plug-and-play capability with leading robot manufacturers, including FANUC®, Yaskawa®, ABB® and Kuka®. It also provides Wi-Fi and Bluetooth connectivity, allowing welding operations to easily access and track essential welding data with the CheckPoint® production monitoring system.

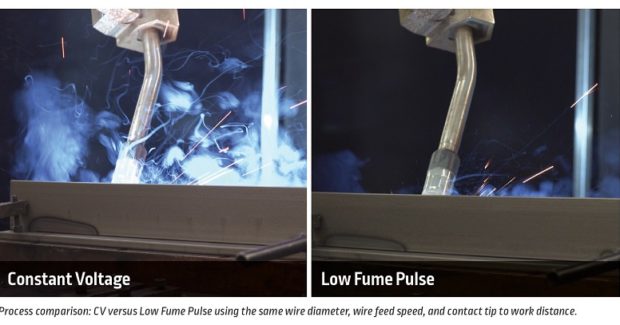

The Low Fume Pulse™ welding process simplifies the balancing act between weld-fume control and weld floor productivity. Developed to be a win-win system, this advanced welding process combines maximum weld performance with low fume generation, providing improved operator productivity and safety at the same time. Engineered to be the first step to overall weld fume control, Low Fume Pulse utilizes Waveform Control Technology to deliver an advanced pulsed waveform that maximizes arc performance while effectively controlling heat-input. In return, this welding process drastically minimizes overall weld fume generation, reducing the volume of weld fume emissions into the workspace by 66 percent compared to traditional constant voltage (CV) MIG. Low Fume Pulse is available as a free waveform upgrade for the Power Wave S500, R500 or R450 with STT or Advance modules.

Lincoln Electric has also launched a new education initiative: the multi-tiered Lincoln Electric Education Partner Schools (LEEPS) program that supports welding instructors at every level, from junior high school to technical college and beyond. At each level, participating instructors may obtain Lincoln Electric qualifications and other benefits by meeting specific program requirements. In addition, schools that meet key requirements may become Authorized Training Facilities, authorizing the school to run Lincoln Electric seminars. LEEPS keeps instructors current and relevant within the welding industry by integrating a professional development system into the program. This provides value to both instructors and administrators at participating schools. “The manufacturing industry will need skilled and knowledgeable welders in the years and decades ahead,” says Jason Scales, the business manager of education at Lincoln Electric. “We are committed to supporting and advancing welding education. This program is a critical component in the ongoing process of preparing educators for advancing welding’s future.”

The LEEPS program is divided into multiple tracks which target instructors that focus on a particular mission or student profile:

- Track 1 is for welding instructors whose students are primarily in the exploratory phase of learning how to weld. This track targets schools and instructors at the introductory, junior high and high school levels, as well as agricultural programs.

- Track 2 takes schools and instructors past the exploratory aspect of welding and into the area of career development and advancement. It addresses the needs of many high school and career center instructors and programs, covering career pathways issues as well as career development.

- Track 3 continues with career development and focuses on advanced manufacturing and processes. The program is typically tailored to the needs of community colleges and technical colleges.

- Schools that meet all requirements of Track 3 may apply to become a Lincoln Electric Authorized Training Facility, which authorizes the school to run Lincoln Electric Training Programs in behalf of the company.

Lincoln Electric has been helping to build a highly skilled welding workforce for more than a century and is dedicated to developing a cadre of qualified welding instructors who will usher in the next generation of highly skilled welders. The LEEPS program is the next leap forward in this ongoing mission. Instructors, administrators and industrial trainers can join this education community by subscribing to the First Pass™ newsletter that delivers the latest information and updates, including curriculum and training materials, as well as education news.

The Lincoln Electric Company, 22801 Saint Clair Avenue, Cleveland, OH 44117-1199, 888-355-3213, www.lincolnelectric.com.