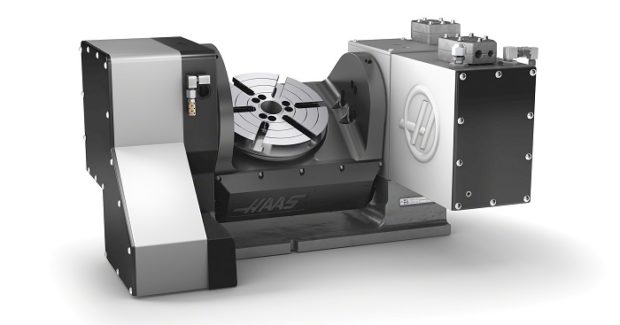

Compact Trunnion Rotary Table Brings 5-Axis Machining Capabilities to the Small Shop

The TR200Y dual-axis trunnion rotary table from Haas puts 5-axis machining capabilities within reach of the average job shop that needs a powerful tool for reducing set-up time and increasing accuracy for complex parts.

Posted: March 9, 2018

Five-axis machining is a powerful tool for reducing set-up time and increasing accuracy for complex parts, but investing in a 5-axis machine tool can be prohibitively expensive, especially for smaller shops. The TR200Y dual-axis trunnion rotary table from Haas Automation, Inc. (Oxnard, CA) puts 5-axis capabilities well within reach of the average job shop, and its compact size provides greater mounting flexibility. The TR200Y is designed to mount in the Y direction (front to back on the table) of a mid-size VMC. At less than 27 in (686 mm) wide and only 20 in (508 mm) deep, this rotary table easily fits on one end of the machine’s table, freeing up the remainder for additional fixtures or vises. It has a 200 mm (7.87 in) T-slot platter and will swing parts up to 8.1 in (206 mm) diameter. The maximum platter capacity is 80 lb (36 kg). The trunnion provides ±120 deg of tilt and 360 deg of rotation for full simultaneous 5-axis motion, or to position parts to almost any angle for machining. Yet it can easily be removed when not needed.

Powerful brushless servomotors provide 150 ft-lb (203 Nm) of spindle torque on both axes of the TR200Y. Brake torque is 300 ft-lb (407 Nm) on the tilt axis and 100 ft-lb (136 Nm) on the rotary axis, speeds are 130 deg/sec on the rotary axis and 100 deg/sec on the tilt axis. The trunnion’s precision-ground platter of heat-treated 4140 alloy steel has six standard 5/8 in (16 mm) T-slots equally spaced at 60 deg for easy fixturing. Plug-and-play compatibility makes connecting the TR200Y to a Haas mill with 4th-axis and 5th-axis drives a breeze, and the available programmable servo control makes it easy to interface the rotary to almost any machine. Built in the U.S., the TR200Y is backed by the worldwide network of Haas Factory Outlets for extensive support and service.

Haas Automation, Inc., 2800 Sturgis Road, Oxnard, CA 93030, 805-278-1800, Fax: 805-988-6918, www.haascnc.com.