External Backstops Ensure Dependable Conveyor Operation in Harsh Environments

BS-F Series backstops from Tsubaki use a unique labyrinth seal that prevents the ingress of dust and other contaminants, minimizes heat generation and provides trouble-free service for maximum life with minimal scheduled maintenance.

Posted: March 16, 2018

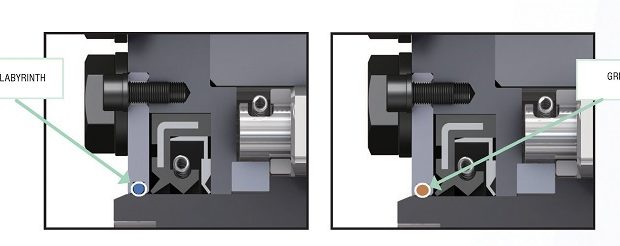

Innovative BS-F external backstops from U.S. Tsubaki Power Transmission, LLC (Wheeling, IL) use a new and improved labyrinth seal design that extends the life of the backstop by minimizing the ingress of dust and contaminants. Synthetic grease is used in place of oil to eliminate the need for oil level checks, routine lubricant inspections, regular oil testing and the breather element – a pathway for contaminants and moisture. These backstops are designed with the smallest envelope dimensions available in the market to assure quick and easy field installation when replacing other manufacturers’ backstops. Their unique, non-roll over cam design offers the highest torque rating available. These key features provide the highest level of performance with minimal maintenance for significant cost savings and improved performance.

Tsubaki also offers innovative Cam Clutches that assure efficient and dependable operation in the harshest environments. The evolution of the uni-directional mechanical clutch started with simple prop and ratchet type designs and has progressed to the roller ramp and non-contact sensing cam type commonly used today. Cam Clutches from Tsubaki transmit torque in one direction of rotation and overrun (freewheel) in the opposite direction of rotation, and all of them utilize the same principles of operation. A wide series of cam clutches is offered to address the many types of applications where they are most often used:

- Backstopping. Clutches are used to prevent reverse rotation of drive shafts that may cause damage to machinery and expensive equipment. The inner race can overrun freely in one direction of rotation. Reverse rotation is instantaneously prevented by the automatic engagement of the clutch. Typical backstop applications are in conveyor systems and gear reducers. Tsubaki has pioneered the non-rollover design.

- Overrunning. These clutches spin freely the majority of the time, occasionally being called upon to lock up and drive. Typical is a two-speed drive where the machine is driven by either an electric motor or geared motor. When the gearmotor drives at low speed the clutch engages. When the faster electric motor drives, the clutch overruns, automatically switching between low speed and high speed.

- Indexing. Reciprocating motion applied to the clutch transforms into one-direction motion. A crank mechanism provides reciprocating motion to drive the cam clutch. The clutch drives in the forward stroke (index) and overruns on the return stroke, indexing the feeding roller forward.

U.S. Tsubaki Power Transmission, LLC, 301 East Marquardt Drive, Wheeling, IL 60090, 847-459-9500, www.ustsubaki.com.