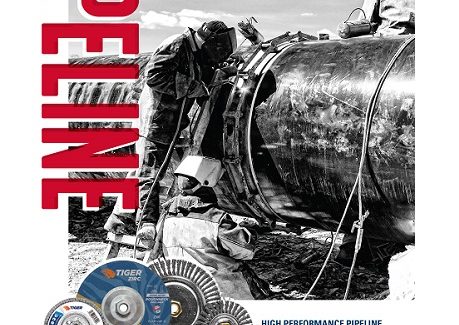

High Performance Cutting and Grinding Tools for Demanding Pipeline Welding Applications

The Tiger bonded abrasives line of tools from Weiler Abrasives includes Roughneck combo wheels for pipeline cutting and grinding, Tiger Zirc grinding wheels for aggressive grinding jobs, and thin Type 1 and Type 27 Tiger Inox cutting wheels for accurate, clean cuts with a contaminant-free bond for worry-free stainless steel applications.

Posted: March 13, 2018

For pipeline applications, Tiger® Roughneck® Pipeliner Wheels from Weiler Abrasives Group (Cresco, PA) are designed for notching and facing applications. They combine a true 1/8 in width for precise material removal, along with the ideal hardness and grain combination for optimal cut/life performance. Roughneck combo wheels are ceramic-infused combo wheels for fast grinding and extended life that are designed to switch between cutting and grinding pipeline applications, lessening the need for additional abrasives. They are thicker than Roughneck Pipeliner wheels that are designed specifically for notching and facing. For hard-to-reach areas, such as corners and fillets, two Type 28 grinding wheels with a saucer-shape design allow aggressive grinding at lower angles – 0 to 45 deg – and with less interference.

Tiger Zirc grinding wheels leverage a self-sharpening Zirconia Alumina grain, along with a ceramic infusion to boost performance, while Tiger grinding wheels feature premium Aluminum Oxide grains for an even, sharp and clean cut. A hard bond on these grinding wheels further extends product life and maximizes performance. Both types of wheels are available in 7 in and 9 in diameters. There are also 6 in and 9 in grinding and combo wheels that provide users with greater flexibility and efficiency when switching between cutting and grinding applications, and a faster-cutting 14 in chop saw wheel that contains Aluminum Oxide grains for cleaner cuts, as well as a softer bond for faster cutting. Thin Type 1 and Type 27 Tiger Inox 7 in cutting wheels deliver accurate, clean cuts, and incorporate a contaminant-free bond that provides a worry-free solution for stainless steel applications.

All of these tools and more are found in the four-page, full color Pipeline Brochure that features high performance stringer bead wheels, bonded abrasive wheels, flap discs and other tools for weld preparation and cleaning on demanding pipe applications. This brochure has been designed to simplify the process of selecting the right product for pipeline applications. Tools in this brochure include the Dually®, Roughneck, Polyflex® and Tiger brands. Its easy-to-read format provides recommendations for tools to use step-by-step before, during and after welding to ensure fabricators have the right tools for notching and facing; removing slag, spatter or light corrosion; and for applying pipe coatings in the field. It also includes recommended maintenance and repair tools, such as their Tiger bonded abrasives for cutting and a variety of scratch brushes for cleaning applications.

Weiler Abrasives Group, One Weiler Drive, Cresco, PA, 18326-0149, 800-835-9999, www.weilerabrasives.com.