Integrated CAM and Tooling Data System Saves Time, Reduces Errors

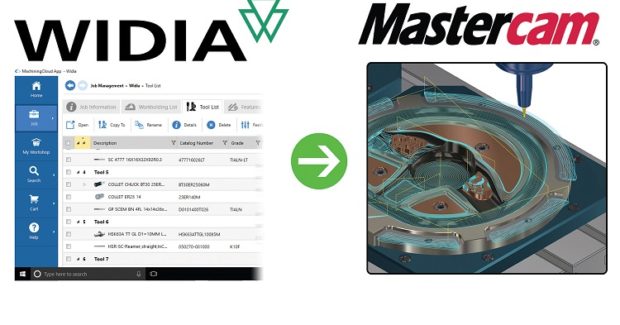

Mastercam users can quickly import tool assemblies from WIDIA NOVO directly into Mastercam 2018, validate and save them in their file and/or Tool Library, and use features such as automated filtering to ensure that holders and tools selected for a particular job can work together.

Posted: March 9, 2018

CNC Software, Inc. (Tolland, CT), the developers of Mastercam software, collaborated with WIDIA Products Group (Latrobe, PA), the original German tungsten carbide tool developers, to develop an integrated system that enables their users to quickly import 3D tool assemblies from WIDIA NOVO directly into Mastercam 2018, validate and save them in their file and/or Tool Library. Features such as automated filtering ensure that the holders and tools that are selected can work together for the particular job. Users now save time by having the correct tooling for the material and for the type of machining operation, plus an accurate 3D model that can be used for visualization and collision checking.

“In the past, users complained of having to search through big complicated catalogs to find related parts, then having to request or build the assemblies from scratch for use in systems such as ours,” said Rich Taft of CNC Software, Inc. “With this integration, users now save significant time searching for desired tools and building 3D tool assemblies that can be brought directly into our software for easy use by most shops. Accurate tool definitions are a critical factor in modern CAM applications. Toolpath algorithms take advantage of these definitions to provide safe and efficient motion. Also, the models that we import from WIDIA NOVO help us to generate accurate in-process stock models that can be leveraged in subsequent operations. Users can also apply these models in verification and machine simulation to catch programming errors before the program ever gets to the machine tool.”

“One of the promises of digitalization in manufacturing is greater precision and speed through effective use of data. This is where integration is a must,” added Chris Merlin, the director of portfolio commercialization at WIDIA. “Users want their systems to work together seamlessly via simple solutions, without extra effort on their part. Now they can effortlessly join cutting tool data with machining data. The 3D models, drawings, and starting parameters are easily available for validation and programming processes. All of this leads to less misapplication of tooling solutions, more optimal machining strategies, and increased productivity with better quality in the manufacturing environment.”

CNC Software, Inc. has also opened Mastercam 2019 Public Beta to all currently maintained Mastercam users. Shops all over the world, from small job shops to Fortune 100 operations, now get a chance to test-drive this version before it is released and provide valuable feedback to help shape the final product. Participants in the Public Beta get an early look at dozens of powerful new tools for simple to complex jobs. Here are a few things they’ll see in Mastercam 2019 Beta:

- New 2D/3D Milling Features improve toolpath efficiency and control. Automate 2D chamfering and multi-axis deburring operations. Accelerated Finishing™ is expanded with taper and lens-style tool support.

- Surface and Solid Modeling Improvements simplify CAD for CAM and deliver greater design and geometry editing tools for shop-floor programmers.

- Powerful Turning and Mill-Turn improve your productivity with new plunge/grooving strategies, additional PrimeTurning™ support, expanded 3D tool and holder support, plus bar feed and import/export operation improvements.

- Improved Validation with new, advanced toolpath display and analysis, plus improvements to machine simulation and support.

- Streamlined workflow and graphics with new sectional views, level and planes management.

. . . and many other productivity improvements across the entire product.

CNC Software, Inc., 671 Old Post Road, Tolland, CT 06084, 860-875-5006, www.mastercam.com.

WIDIA Products Group, 1600 Technology Way, Latrobe, PA 15650, 724-539-5000, www.widia.com/novo.