Machining Software for Programmable Class 5 Smartmotor

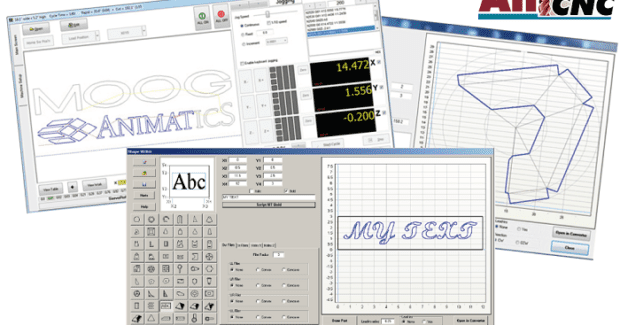

The AniCNC software system from Moog Animatics provides a graphical HMI, G-code editing and runtime environment, and other built-in features to tackle milling, routing, machining, shaping and related projects with their Class 5 SmartMotor.

Posted: March 12, 2018

Moog Animatics, a division of Moog Inc. (Mountain View, CA), offers their AniCNC™ application software that is exclusively for use with their Class 5 SmartMotor™, a highly programmable servo motor system that is integrated with a motor, an encoder, an amplifier, a controller, RS-232/RS-485 and other optional communications and IOs. This motor provides a smaller footprint, a lower total cost and a simplicity to reduce machine development and build time. When coupled with the Class 5 SmartMotor, the AniCNC software system provides a graphical human-machine interface (HMI), G-code editing and runtime environment, and other built-in features to tackle milling, routing, machining, shaping and related projects. An offline mode allows preview and refinement of G-code tool paths without being attached to the SmartMotor. Additional features include:

- A simple, intuitive user interface, optimized for touchscreen use.

- Advanced Code Writer and Shape Writer for creating complex patterns.

- DXF file import to produce scalable G-code for quick resizing and/or arraying.

- G-code export to DXF format for efficient use in CAD or illustration software.

- G-code editing and runtime environment with real-time viewing of the tool path.

- TrueType font to G-code converter allows text scaling/framing.

- Built-in functions for point-and-click programming of common metalwork shapes.

- Nested-array code building for easy duplication of parts in sheet material.

- Dynamic jog and teach to rapidly record points to the G-code program.

- In-path jog correction allows temporary move adjustment and then resets and continues.

Moog Inc., 2581 Leghorn Street, Mountain View, CA 94043, 650-210-9000, Fax: 650-210-9001, www.animatics.com, www.moog.com.