Superabrasive Wheels Grind Difficult Materials Substantially Faster

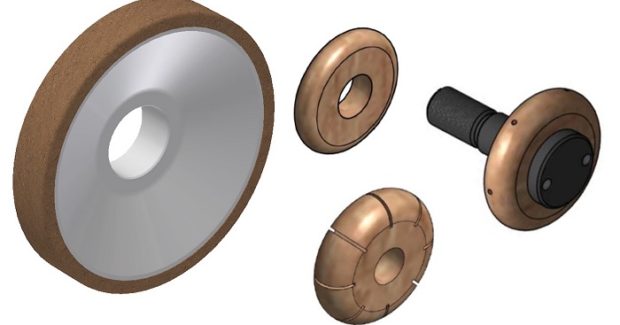

HPL Grinding Wheels from Meister Abrasives combine high-end CBN crystals fixed with durable, porous, intrinsically lubricated bonding matrix to allow substantially faster grinding of difficult materials.

Posted: March 13, 2018

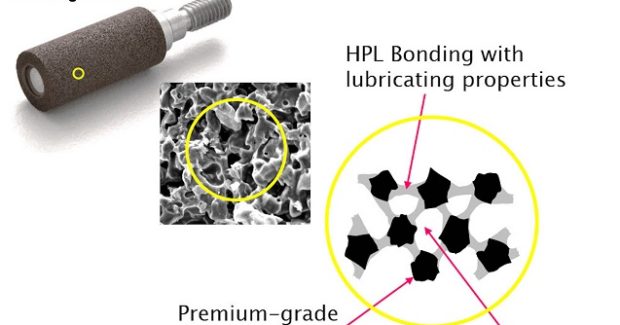

HPL (High Performance Lubrication) Grinding Wheels from Meister Abrasives USA Inc. (North Kingstown, RI) rely on premium grade CBN crystals fixed with durable, porous, intrinsically lubricated bonding matrix to allow substantially faster grinding of difficult materials without sacrificing quality due to wheel loading and/or part burning. “These HPL superabrasive wheels are a significant extension of our proprietary HPB (High Performance Bonding Technology),” said Dr. Peter Beyer, the chief executive officer and chief technologist for Meister Abrasives. “It departs from conventional approaches to manufacturing wheels with lubricating properties that rely on fillers that can clog the wheel’s pores and are less likely to distribute lubricating properties evenly.

HPL wheels contain a lubricant that is intrinsic to the bonding matrix chemistry and is released uniformly as the wheel breaks down. Wheels manufactured with this technology minimize friction from bond/work piece interactions, minimize heat generation, and deter the onset of metal loading into the bond structure. HPL technology also makes it possible to implement wheel characteristics that are not economically feasible with standard vitrified bondings. The superior grit retention and lubricating properties of the bond make it possible to utilize high concentrations of premium grade CBN crystals that in a standard bonding matrix would generate too much pressure and heat. This allows Meister to manufacture wheels with superior cutting performance and wear resistance to others on the market. The unique properties of these intrinsically lubricated wheels address a wide range of problems, including burning of parts, wheel loading, excessive wheel wear due to heat related issues, and quality issues due to temperature sensitive materials.

“Early adapters in Europe and the United States have tested dozens of application-specific HPL recipes with excellent results,” noted Dr. Beyer. “Although the extent of performance improvements varies from application to application, I can say that users rarely switch to a new technology for existing production grinding applications if they are not realizing a 25 percent or better improvement in productivity.” Applications for HPL abrasive technology include:

- Deep bore grinding with limited coolant access, such as fuel injection nozzle components.

- Blind-end bore grinding such as lash adjusters and tappets.

- Heavy-stock form grinding applications such as electronic power steering (EPS) ball-nut tracks.

- Creep-feed grinding of tool steels and superalloys.

- High stock removal out-of-round grinding for punches.

- Any application where the concentration of oil and lubricant are less than ideal or the flow of the coolant is impeded, as is the case with deep bores.

HPL CBN grinding wheels are available for both internal and external grinding with mesh sizes ranging from 60 to 1200.

Meister Abrasives USA Inc., 201 Circuit Drive, North Kingstown, RI 02852, 401-294-2530, Fax: 401-294-7326, sales@meister-abrasives-usa.com, www.meister-abrasives.com.