Train Operators on Eight Different Machine Controls with One Turning Center

The modular Industrial Training system from EMCO prepares employees for specific production requirements with an innovative virtual learning environment that uses intelligent courseware for training over a range of common CNC machining center and turning center controls.

Posted: March 8, 2018

With intensifying competition and ever-increasing requirements for quality, productivity and flexibility, demands for well-qualified employees continues to grow. To help shops with their machine tool training needs, the modular Industrial Training system from EMCO Maier Corporation (Novi, MI) prepares employees for specific production requirements with an innovative virtual learning environment that uses intelligent courseware for training over a range of common CNC machining center and turning center controls. The E[MCO] CAMPUS includes over 700 learning maps, videos, interactive achievement tests, explanatory texts, and images, and allows tutors to create individual curricula and dedicated content using an authoring tool.

Trainees work through four courses, including Machining Technology, CNC and Quality in a relaxed learning environment. All courses are designed in accordance with professional educational principles and use the most appropriate media. Whether a newcomer, machine operator/setter or machining technician, all course contents are designed to match the individual student’s level of knowledge. Tests at regular intervals provide trainees with the necessary feedback on what they have learned at each stage. The EMCO CAMPUS is the ideal way to promote classroom teaching of basic theory and principles in 5-axis technologies and counter-spindle applications. Trainees are encouraged to adapt what they learn to their individual needs and continuously monitor whether their learning objectives are being met.

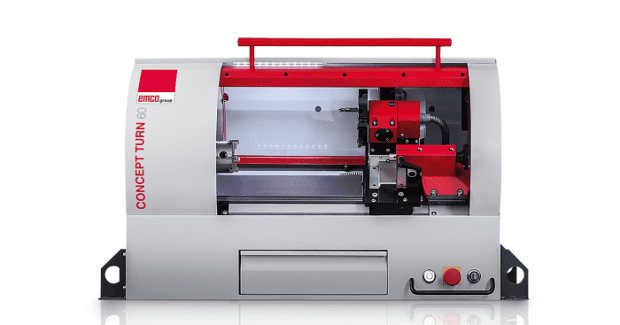

Trainees then apply what they have learned on a high performance Concept TURN 60 PC-controlled, 2-axis CNC turning center, where the conversion from one control to another control system is carried out within a minute by calling up the respective software and simply replacing the controller specific module. Up to eight different control systems can be installed and taught on a single machine that uses the latest WinNC control unit. Easy2Control is a software option that offers control-specific keys and touch functionality for WinNC controls on a 16:9 Full HD screen. It is no longer necessary to manually switch control panels with this option because the responding panels appear on the screen when opening specific control software and can be switched via tabs for fast access. As an alternative, the machines can also be controlled directly without an external PC with easy to use EASY CYCLE software that is based on cycle programming and can be downloaded for free from EMCO’s homepage. Win3D-View provides realistic 3D simulation of machining processes and machine periphery that allows the trainee to see part manufacturing directly on the screen.

The machine base and headstock of the CT 60 are made from grey cast iron. The inclined-bed design, profile rail guides and warp-resistant box construction provide high levels of rigidity and robustness that ensure high precision in a very small footprint. The tool turret is positioned above the center of rotation. There are eight tool stations and the tool cross-section is 12 mm x 12 mm. The enabling switch and operating mode selection switch to run the machine are based on the current turning machine standard ISO 23125. The spindle bore is ø16 mm. A Lenze drive system for the main spindle ensures high rotational speeds at equally high torques with good acceleration times, with 1 kW of drive power and a maximum speed range is 300 rpm to 4,200 rpm. Maximum X-axis travel is 60 mm and Z-axis travel is 280 mm, with rapid X/Z motion speeds of 3 m/min.

EMCO Maier Corporation, 46850 Magellan Drive, Unit 160, Novi, MI 48377, 248-313-2700 Fax: 248-313-2701, www.emco-world.com.