Accelerated Fabrication of Complex Stamped and Wire Components for Appliances

The 4Slide NC system from Bihler features variable production speeds up to 250 ppm that combine with a standard servo clamp feed or optional endless “caterpillar” feed to reduce manufacturing times by up to 50 percent for a variety of part sizes.

Posted: April 14, 2018

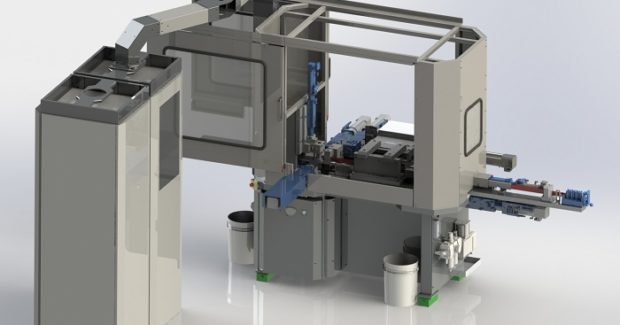

The technology in the advanced servo-controlled 4Slide NC system from Bihler 4Slide-NC (Phillipsburg, NJ) represents a significant leap forward in design, performance and dependability to modernize and accelerate parts manufacturing and assembly of complex stamped and wire components. It also addresses one of the biggest pain points among manufacturers: the high capital investment required to transition from old 4Slide machines. The introductory 4Slide NC model is competitively priced, with several financing options available and tooling compatible to select mechanical 4Slide machines. A rapid path to ROI is achieved through more effective use of run times, less down time for switchovers, and the ability to efficiently accommodate small to very large orders. “The 4Slide NC is far more than another faster, better machine,” noted Max Linder, the director of sales and marketing for Bihler. “It puts users on a path to running a higher quality, highly responsive, and much more profitable manufacturing business.”

The 4Slide NC unit features a standardized control system that integrates seamlessly with any Bihler process module. The unit is also compatible with select mechanical machines, allowing shops to readily integrate it into their existing operations. This allows a shop to maintain or grow profitability by quickly and simply incorporating tools from their existing machines to the new 4Slide NC technology equipment. In response to fulfilling “need it now” customer orders, the 4Slide NC is highly efficient at producing small lot sizes for evaluation or immediate order fulfillment, thanks to extremely short set-up times and faster production speeds that enable manufacturers to complete small orders rapidly, often in less than half the time as traditional methods. Changeover/conversion times are reduced by as much as 80 percent, with productivity increases as high as 100 percent over traditional systems.

The 4Slide NC is designed with ease-of-use in mind. It features a trusted VariControl VC1 machine and process controller installed in a modular stand-alone cabinet. A 15 in TFT touchscreen provides intuitive user-friendly commands, ensuring seamless operation and process monitoring. The automation tasks needed to accelerate the manufacturing process are accomplished with this highly intuitive control. The 4 Slide NC features variable production speeds up to 250 ppm that, when combined with the standard servo clamp feed or the optional endless “caterpillar” feed, can reduce manufacturing times by as much as 50 percent. A robust 7 ton or 21 ton press capability and 4.7 in (120 mm) servo grip feed ensure the unit is suited to cutting and stamping applications for a variety of part sizes. Among its many applications, the unit is ideal for the efficient production of strip and wire parts, and is suitable for both batch and full-scale production orders. All 4Slide NC machines are backed by Bihler’s warranty and full service support program.

Bihler 4Slide-NC, 85 Industrial Drive, Phillipsburg, NJ 08865, 908-213-9001, Fax: 908-329-9111, www.4slide-nc.com.