Advanced Waveform System Addresses Thin-Gauge Steel Welding

The new AC STT waveform from Lincoln Electric provides a complete system for welding thin sheet metal from 24 ga and up, while accommodating for poor fit-up and gap conditions.

Posted: April 17, 2018

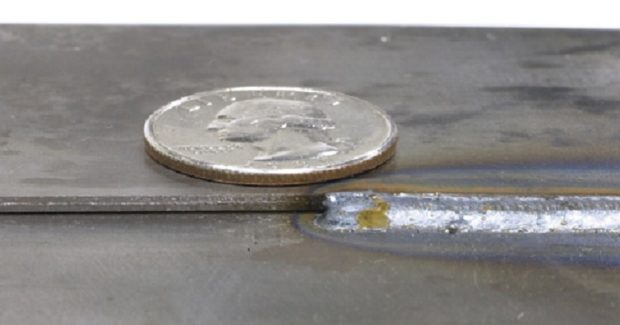

The Lincoln Electric® Company (Cleveland, OH) expanded their patented STT® (Surface Tension Transfer) welding process to work with thin-gauge materials. The new AC STT waveform provides a complete system for welding thin sheet metal from 24 ga (0.6 mm) and up, while accommodating for poor fit-up and gap conditions. STT, a modified short-circuit GMAW process, was originally engineered as a low-spatter system for root-pass pipe welding. It’s cold enough to bridge gaps, but also hot enough to produce a robust back bead. AC STT combines STT low-spatter technology with the control heat-input characteristics of AC GMAW welding, helping to further reduce burn through while maintaining high deposition rates. AC STT is available as a free waveform upgrade for the Power Wave® S500, R500 and R450 with the Advanced Module.

Lincoln Electric also added Blueprint Reading – a comprehensive, multi-lesson curriculum module aimed at understanding and working from a typical welding blueprint – to their U/LINC® welding and cutting curriculum program. Each lesson in the Blueprint Reading series includes a lesson plan, student reference, presentation and quiz, while some also feature a lab activity to reinforce skills learned. All lessons incorporate symbols and terminology pertaining to American and ISO standards, making them a valuable training resource for instructors and students anywhere in the world. Blueprint Reading lessons will help students master key skills including understanding the use of different scale types used on drawings; identifying height, width and length dimensions; interpreting welding symbols and notations; and drawing multiple view sketches. Mastering these skills enhances welding careers across multiple industries and disciplines, including fabricators, related trades and engineering.

“Many educators have been asking us to tackle a blueprint reading module,” says Chris Gandee, the manager of Lincoln Electric Education Services. “Following development and testing, we’re excited to launch this comprehensive group of lessons for welding career school programs.” With a unique insight into the issues that shops face every day and the skills they need from workers to meet today’s demands, the U/LINC system is well-positioned to help educators provide welding training to students at every level: high school, trade school and college, as well as mid-career welders looking to enhance their skills or those changing careers. U/LINC turns insight and expertise into an effective, ready-made welding curriculum aimed at training a new generation of welders for the manufacturing landscape of the 21st century that is defined by increasingly high standards of quality, productivity, efficiency and regulatory compliance.

Blueprint Reading expands the scope of U/LINC, making it the most comprehensive option for career tech welding and cutting curriculum. “Employers in every industry demand this skill, and it’s important for schools to cover this material to make their graduates more marketable,” adds Gandee. “Students will appreciate mastering an additional skill that will help them throughout their career.”

The Lincoln Electric Company, 22801 Saint Clair Avenue, Cleveland, OH 44117-1199, 888-355-3213, www.lincolnelectric.com.