Don’t Spec a Welding System Until You’ve Done This

While increasing throughput, improving product quality, dealing with labor shortage and right-sizing a robotic cell are valid factors to consider when pricing out a system, the best designed system can still miss the mark. You should really pay more attention to these two factors before diving too deep into cell design and component specifications.

Posted: April 24, 2018

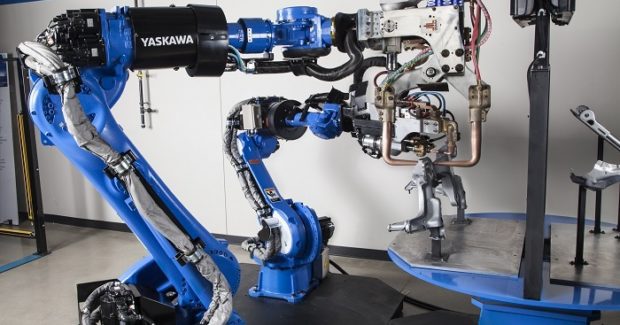

Historically, the prevailing thought has been that robotic welding systems can’t handle the diversity of tasks required for difficult weldments, but technology has changed. From improved welding process capabilities to enhanced laser sensing and technologies, advanced robotic welding solutions are making it easier for shops to tackle the most difficult, dangerous and dirty tasks. When fabricators are faced with a welding process that could potentially benefit from automation, where’s the best place to begin? The instinct is to dive right into specifying the cell design and required components. However, current trends in manufacturing are driving more attention to calculating return on investment (ROI) and gauging payback (time).

While increasing throughput, improving product quality, dealing with labor shortage and right-sizing a robotic cell are valid factors to consider when pricing out a system, it’s also important to understand the potential financial gains of the robotic welding solution over the course of a targeted payback period. Our Robotic Welding System Payback Calculator gives shops a budgetary target for a robotic system that meets payback and productivity requirements. Not only can the derived calculations serve as a financial guideline, but the same figures can also be used to establish goals and expectations. The workcell value calculation assumes that one robot in a system can do the work of three and a half welders and is affected by the following key inputs:

- Desired system payback period.

- Straight labor replacement.

- Additional productivity gains from system.

- Other savings through reduced materials costs, quality improvement, etc.

While significant cost savings can occur over the 10-year to 15-year lifespan of a robot (30,000 hours to 40,000 hours with proper maintenance and possible refurbishment), most shops plan to reach ROI within a two-year payback period. So why is it crucial to proactively bring these calculations into your decision making? Consider this hypothetical purchasing situation:

https://youtu.be/RdUBIezIyzc

THE BEST DESIGNED SYSTEM CAN STILL MISS THE MARK

A manufacturing plant, struggling to meet daily quotas, sought to purchase a robotic welding system. The existing process involved five workers at five different stations, spanning two shifts. However, an occasional labor shortage due to vacation or sick time – with no skilled laborers available to fill the void – made product quotas hard to achieve. Management determined that an investment in robotic automation would be advantageous to their current operations and spent months evaluating each work station, developing specifications for a system that would be perfect for their process and capable of meeting daily quotas. Certain that a robotic workcell – based on process needs alone – would be an ideal solution, they bought a welding system.

Once the system was installed and running at full capacity, leadership realized something: even though daily quotas were being reached (despite occasional labor shortages), the numbers were showing that the payback period for their investment was now too long to justify the purchase. The company failed to clearly define their business expectations and apply that knowledge to their equipment investment. If ROI targets had been determined upfront, the chosen system could have been built with key requirements in mind.

Estimating a realistic budget to meet defined business goals makes system design a more focused and productive undertaking. Upon commissioning of a new system, ramp-up time can be critical to meet target payback periods. In most cases, a standard workcell can be a perfect fit. Not only are these pre-engineered systems easy to integrate and operate, but they also offer exceptional design and optimal configuration options for parts of all sizes. For unique applications, there are customized systems available that are equipped with world-class components to meet specific needs. Robotic welding systems have come a long way in the past decade and are able to provide game-changing advantages for users spanning diverse industries. Understanding the cost savings associated with a long-term approach to automation is essential. Only then can shops make the most profitable decision when it comes to choosing a robotic welding system.

Zane Michael is the director of thermal business development at Yaskawa America, Inc., Motoman Robotics Division, 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, Fax: 937-847-6277, www.motoman.com.