Forklift Manufacturer Relies on Simulation Software

To improve productivity in their robotic welding operations, Crown has begun to replace the time-consuming manual teaching of their robot systems with simulation-based offline programming for tool path generation.

Posted: April 10, 2018

Crown Equipment Corporation (New Bremen, OH) is one of the five largest forklift manufacturers in the world. The family-owned business has a global production, sales, and service network with 19 manufacturing sites around the world and more than 500 sales offices in 84 countries. As a customer-oriented innovation leader, they regularly set trends in the field of material flow systems. For the production of forklifts, it is critical to develop robust and durable equipment that meet the user’s high demands for quality, ergonomics and reliability, as well as meeting safety-relevant requirements. High quality standards, based on a customer-oriented focus are met by Crown’s high vertical integration: up to 85 percent of the components they use are produced in-house.

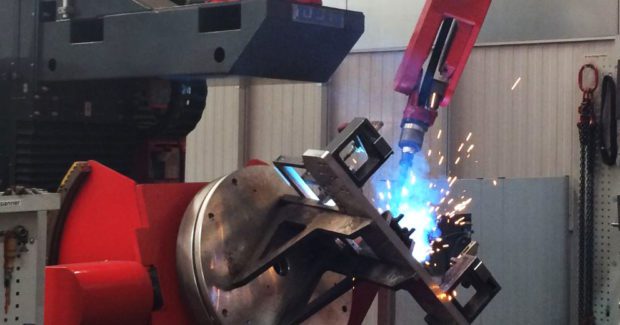

The company has built forklifts in their Roding, Germany, facility since 1986 and today they use several complex robot systems (with up to 13 axes) on the production floor. Programming and fixture construction play an important role, but some of the solid steel components have seams that are difficult to access, while others have many welds in a small area. Both applications make manual teaching and fixture construction difficult. The shop had considered using offline programming for some time and Florian Braun, a project manager in manufacturing engineering, saw an opportunity to optimize the use of welding robots.

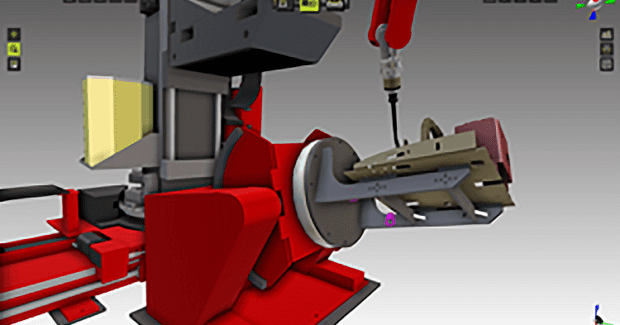

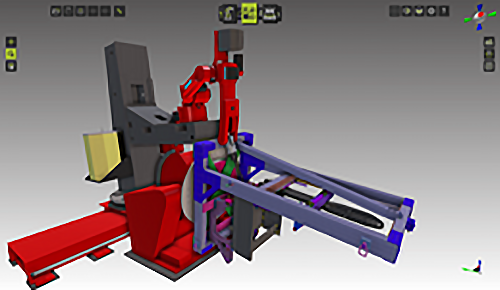

IT and software consulting company CENIT AG (Stuttgart, Germany) convinced them that FASTSUITE Edition 2 software could fulfill their welding requirements: The 3D simulation platform offers a sophisticated technology package specifically for offline programming of welding processes. A benchmark was set to program a component with the OLP software on a Reis compact weld cell and perform a download. Above all, it was judged how well the download works and how close the robot follows the contour of the weld path. The software features required by Crown include:

- CAD data-based welding seam generation (CAD-to-path algorithms) with automatic approach and departure strategies. Welding path generation not only describes the robot’s motion paths, but also includes the control commands for the welding technology. In this way, many manual programming steps are avoided and optimal process parameters are always used.

- The parameters for the weld seams and the positioning of the torch to the workpiece can be easily adjusted if required.

- External axes and workpiece positioners are automatically positioned and interpolated.

The performance of FASTSUITE in the field test was convincing. Although the cell had not yet been calibrated and prepared for offline programming during the test, the toolpath was already very close to the expected result on the test part. FASTSUITE was able to demonstrate its “ease of use” and the high level of expertise in welding production that CENIT brought gave Crown additional assurance that they had found the right partner. The implementation project had three phases: At startup, CENIT configured the software for the requirements of the corresponding system (Phase 1). This was followed by the creation of a digital layout model of the cell (Phase 2) that corresponds to the real installation. In the shop, Phase 3 began with the calibration of the facility with the digital model.

The first welding cells were integrated into the simulation environment at the beginning of summer 2017. Instead of taking several days, programming a new workpiece or part variant now only takes a few hours because the programming takes place in the simulation environment of FASTSUITE Edition 2 (offline, i.e. parallel to the productive operation of the system) and as a result, the downtime of the system has been significantly reduced. The production interruptions for setting up and teaching new components has also been reduced to a minimum. The welding quality of the solid steel parts are consistent and corresponds to Crown’s high standards.

The OLP project has had a positive impact on streamlining the development and design of toolmaking. It is much faster and easier to determine the right fixture because the simulated system is available with all of the kinematics and peripherals as a virtual 3D model. Instead of testing the real device prototypes over and over, the virtual device can be tested for accessibility and then built in real life. New components can be optimized during development for later welding production. New ideas are already emerging in the Roding facility today. With FASTSUITE, Crown has a software system that they can grow with that is open and scalable – and an ideal first step for a shop with a strong Industry 4.0 vision.

CENIT North America, Inc., 691 North Squirrel Road, Suite 275, Auburn Hills, MI 48326, 248-276-8540, Fax: 248-377-1652, www.cenit.com.