Guided Pierce Cylinders for Appliance Manufacturing

These hydraulic cylinders from Coldwater Machine feature an internally self-lubricated, guided rod inside a steel cylinder body that provides stable, non-rotating performance with the ability to reach hydraulic pressure of up to 3,000 psi.

Posted: April 11, 2018

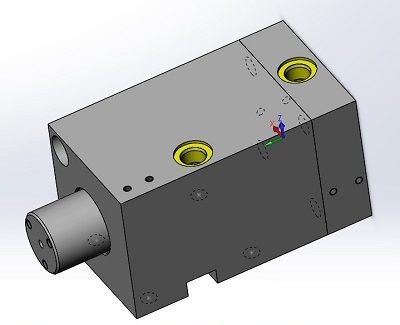

Coldwater Machine Company (Coldwater, OH), an automation supplier that manufactures and integrates assembly automation and special machines, has designed their own guided rod cylinders for use in their fabrication equipment systems for punching, piercing, and notching. These hydraulic cylinders feature an internally self-lubricated, guided rod within a cylinder body. This provides both improved reliability and less maintenance. And since there are no external guides, this cylinder design is very compact, requiring a third less space than alternatives. “These standard design cylinders enable us to offer more robust and flexible systems to users,” said Paul Link, the head of technology at Coldwater. “They’ve proven to be both a reliable and compact alterative in a number of our systems. Applications include piercing, forming, joining, and assembly pressing.”

The guided pierce cylinders feature a steel body and provide stable, non-rotating performance with the ability to reach hydraulic pressure of up to 3,000 psi. Coldwater is currently building two sizes based upon their most common system requirements. These cylinders are used in systems for appliance manufacturing, including dishwasher panel and washer cabinet lines, as well as for automotive frame and body piercing lines.

Coldwater Machine Company, 911 North Second Street, Coldwater, OH 45828-8736, 419-678-4877, www.coldwatermachine.com.