Keeping Tube and Pipe Joints Clean When Welding

Huntingdon Fusion Techniques HFT can remove air from the vicinity of a weld inside and outside simultaneously by using a Weld Trailing Shield on the outside and an Inflatable Pipe Purging System on the inside.

Posted: April 18, 2018

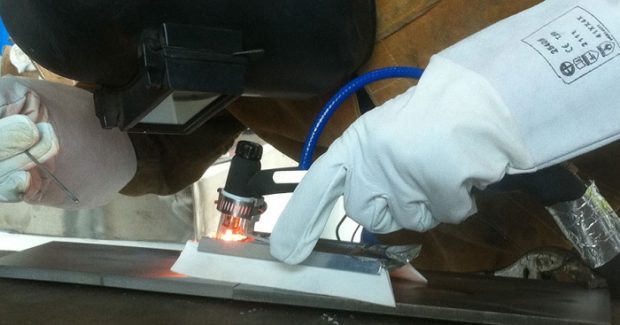

It is important when welding stainless steel and titanium tube and pipe joints to be able to have zero color, oxide-free welds both on the inside and outside. To achieve the conditions for zero color, or oxide-free weld joints, it is necessary to remove the air around the joint to a level where the oxygen percentage is somewhere between 5 ppm and 50 ppm, subject to the metal and, to some extent, the application. Removing the air from the vicinity of the weld inside and outside has to be carried out simultaneously and this is best carried out on the outside with an accessory called a Weld Trailing Shield® and on the inside with an Inflatable Pipe Purging System from Huntingdon Fusion Techniques HFT® (Burry Port, Wales).

The Trailing Shields are light in weight and are carried easily by the welder as the torch is moved around the seam. As the sides are fused together, the hot metal is shielded for a very short time by the inert argon gas flowing through the welding torch and out of the ceramic gas cup. At this time, the Trailing Shield that has also been connected to an argon supply takes over and shields the hot metal until its temperature falls below its oxidation level, thus leaving a perfectly clean weld. In the meantime, inside the pipe, two inflatable dams tightly seal a cavity about 10 in (250 mm) either side of the joint. An argon gas supply pushes the air out and it exits through a Weld Purge Monitor® that indicates when the air has achieved an oxygen level below 50 ppm, or any other level as required by the WPS (welding procedure sheet). At that time, the welder begins his process.

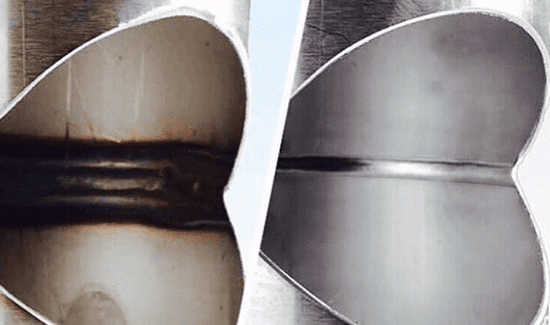

Without such accessories, welding is performed in an oxidized environment that leads to loss of corrosion resistance and results in metallurgical imperfections in the joint. Oxidized welds incur a penalty for the fabricator, who must ensure that oxidation and discoloration are totally removed by mechanical or chemical means. Such additional work can have an effect on profitability and on delivery time. Notice the super clean outside of the weld in the video below.

https://youtu.be/9XlXBuY01iU

COB Industries Inc., PO Box 36-1175, Melbourne, FL 32936-1175, 321-723-3200, www.cob-industries.com.