Workholding Systems for Part-Specific Automotive Machining

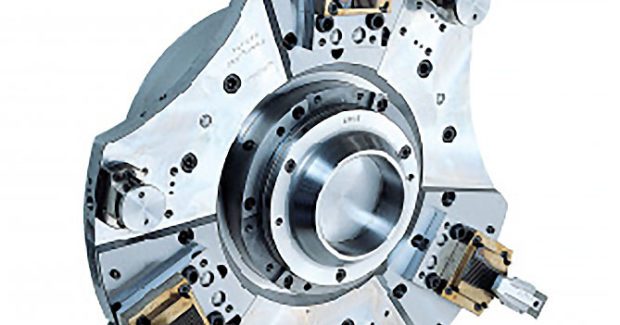

Cutting-edge chucks and custom fixtures from Kitagawa North-Tech are engineered, modified and/or customized to solve part specific machining for a myriad of automotive applications.

Posted: April 16, 2018

The new suite of Automotive Industry Workholding Solutions from Kitagawa North-Tech, Inc. (Schaumburg, IL) bundles together advanced and custom engineered workholding products that are ideally suited for automotive machining applications. This advanced workholding series include cutting-edge chucks and custom fixtures that have been engineered, modified and/or customized to solve part specific machining for a myriad of automotive applications, including camshafts, valves, cylinder pumps and heads, differential cases, brackets, clutches, covers, holders, gears, hubs, pinions, pulleys, rotors, rollers, pistons, chassis components and more.

These chucks and fixtures feature high gripping stability and excellent repeatability. The suite includes:

- DL200 – dual locking chuck with increased gripping options and easy jaw forming; ideal for high volume automotive machining applications.

- PWc and PWTc – two- or three-jaw power wing chucks with powerful gripping for irregular work pieces and tapered parts. Provides secure gripping for casting and forging applications.

- PU Type Pull Lock Chucks (PU, PUB and PUE) – draw-down chucks for high precision processing available with open center types. High radial gripping forces and strong pullback action allows for stable cutting under heavy load conditions.

- FG Finger Chucks – for high speed turning of three-jaw wheel chucks for automotive and motorcycle aluminum wheels, and six-jaw chucks for OTR trucking applications.

- Collet Chucks – short series collet chucks, long series collet chucks, quick change collets chucks and pull back collet chucks.

- Custom Fixtures – weldment or casted base custom fixtures for a variety of horizontal and vertical machining applications.

Custom engineered turning and prismatic workholding systems are typically required for complex, part-specific automotive machining jobs. In situations where a standard and advanced chuck or fixture does not meet the rigid process requirements of a unique part-specific automotive machining application, a fully customized, engineered workholding system may be required.

Kitagawa NorthTech’s Productivity Team is utilized to help analyze, design, manufacture and test a fully engineered and custom workholding solution for customers. They have the expertise at designing, engineering and manufacturing an extensive range of workholding and tooling for automotive turning and prismatic applications. The company also leverages their in-house manufacturing, engineering, testing and production group to provide a turnkey, tightly integrated system that will meet or exceed customer requirements.

Kitagawa North-Tech, Inc., 301 Commerce Drive, Schaumburg, IL 60173, 800-222-4138, kitagawa.com.