Advancing Additive in Aviation

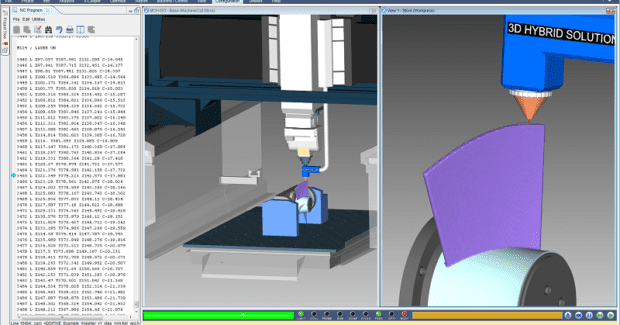

By integrating VERICUT software from CGTech with metal printing technology on a CNC machine tool, 3D-Hybrid Solutions can apply powdered metal or wire feedstock at rates up to 20 lb per hour, then machine the part to precise dimensions on the same machine with no need for secondary fixtures.

Posted: May 29, 2018

As the aerospace world embraces 3D metal printing, GE Aviation (Evendale, OH) uses it to print fuel nozzles and save aircraft owners millions in operation costs annually per plane. But there’s only one problem: despite its awesome capabilities, metal 3D printing requires secondary processing – machining or grinding – to remove any support structures used during the build process, and often needs additional machining to achieve the desired part accuracy and surface finish. 3D-Hybrid Solutions Inc. (Seal Beach, CA) knows this. As their name implies, the company leverages a hybrid approach to 3D printing. By integrating metal printing technology with a CNC machine tool, it’s possible to apply powdered metal or wire feedstock at rates of up to 20 lb per hour (in some applications), then machine the part to precise dimensions on the same machine. There’s no need for secondary fixtures because internal holes and channels can be machined before being “closed up” during printing, part accuracy is improved, and processing times are substantially faster than with conventional 3D printers.

“Aside from the relatively slow build speeds, that’s the biggest drawback with 3D printed metal,” noted Karl Hranka of 3D-Hybrid Solutions. “Secondary machining of some sort is almost always needed, and on larger workpieces, such as molds and aerospace components, this can mean a lot of unnecessary production expense and lead time. In most cases it makes good sense to do this machining while you’re actually building the part in order to machine hard-to-reach features. By consolidating the two technologies, you can achieve broader capability and greatly reduce total capital investment costs and operating costs. The risks in moving a 5-axis deposition head around a workpiece whose geometry is continually changing are obvious. And being that many of 3D-Hybrid Solution’s potential customers employ large, expensive machine tools, the need for a toolpath simulation and verification tool became abundantly clear. To address these concerns, they joined forces with CGTech (Irvine, CA), which has a verification tool aimed specifically at additive manufacturers.

“Whether additive or subtractive machining, we consider ourselves experts in CNC machine kinematics, control technology, how the toolpaths and G-codes interact on a machine,” said Gene Granata, the VERICUT product manager at CGTech. “Our software simulates the same NC program that will drive the CNC machine, ensuring the highest level of verification possible. This makes it a perfect fit in a hybrid machining situation. Not only can users check for the usual concerns, like over-travels and tool collisions, but they are also able to verify additive specific conditions: what’s the layer thickness, how much stepover was used, and whether the proper gas and laser codes and settings are used to assure a robust build.” Some key points of VERICUT software include:

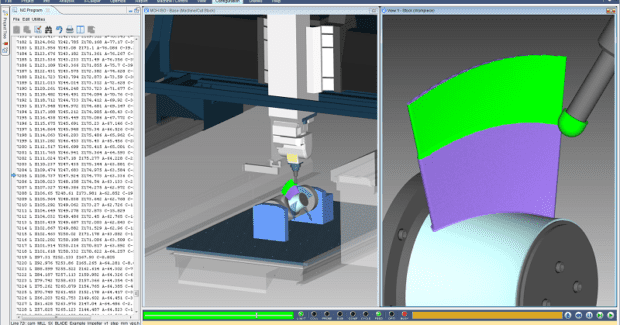

- Operators are able to “add-cut” or “cut-add” material, in any order and with any type of machining done, whether it’s a 5-axis CNC machining center, multitasking turn-mill lathe, or deposition-style robot.

- The ability to accurately simulate the actual G-codes provides users with the assurance that hybrid machine tools will be protected from expensive crashes, and avoid setups that “just don’t work.”

- Laser parameters and material deposition rates controlled directly by additive codes in the post-processed NC program are verified for proper additive functions and ranges.

- A realistic view of additive material deposition is provided: it’s very easy to differentiate deposited “unfinished” material from previously machined features.

- Using the AUTO-DIFF gouge check feature, voids and missing material are clearly visible, eliminating the chance for costly rework or potential part failures.

- Unique “droplet” technology provides programmers with detailed history of the build process and makes it easy to identify the exact source of problems via a single click, regardless of how many toolpaths or even setups are used to manufacture the part.

“Shops are really catching on to what’s possible with additive manufacturing, and the ability to machine parts and fabricate tooling in the same process brings that much more to the table,” adds Granata. “There’s nobody else out there doing this level of validation, or making the process look as realistic. It’s going to make the technology much easier and safer for companies to adopt.”

3D-Hybrid Solutions Inc., 1527 Seal Way, Seal Beach, CA 90740, 309-264-4834, info@3dhybridsolutions.com, www.3dhybridsolutions.com.

CGTech, 9000 Research Drive, Irvine, CA 92618-4214, 949-753-1050, info@cgtech.com, cgtech.com.