Automatic Sawing of Structural Steels, High-Tensile Strength Solids and More

Perfect for production cutting, steel service centers and job shops, the HBE-261A Dynamic, the HBE320-523G Dynamic, and the HBE663A Dynamic band saws from Behringer Saws are ideal for a wide range of applications, including heavy duty sawing of structural steels and high-tensile strength solids.

Posted: May 30, 2018

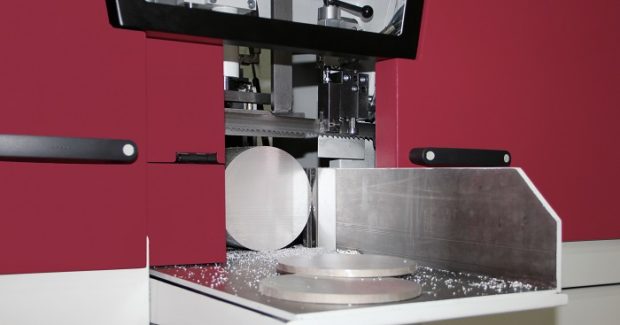

In Booth N-236844, Behringer Saws, Inc. (Morgantown, PA) will display an array of their high performance, automatic HBE Dynamic band saws that are designed to be an everyday workhorse through their affordability, versatility and efficiency. These compact band saws have a multitude of leading-edge features designed to improve performance and precision while maximizing user convenience and safety. Among the line-up of Dynamic band saws are the HBE-261A, HBE-321A, HBE-411A, HBE-511A, HBE-663A, HBE-860A, HBE-1060A, and the HBE-320-523 automatic and semi-automatic miter band saw. Ideal for a wide range of applications, from production cutting, steel service centers to job shops, these band saws are made for heavy duty sawing, including structural steels and high-tensile strength solids. Cutting capabilities range from 10.2 in to 42 in, and blade sizes from 1.25 in to 2.625 in.

With a broad range of options, the HBE can be configured to support the user’s application, with bundle clamping, extended feeding grippers and much more. Many features are available to make production even more profitable: Each saw is made of vibration-damping grey cast iron that provides solid and durable construction, along with a sensitive downfeed control system, precise guiding system in portal design, energy-efficient drive system, electrically-driven chip brush synchronized with blade speed, and easy operation by an intuitive NC control system. The innovative servo-driven ball screw blade feeding system and pressure sensors automatically provide precise, constant downfeed control and adjustment to continually optimize the cutting process. The ball screw-driven material feed gripper eliminates backlash and ensures precise material positioning and repeatability. A fully enclosed design promotes safe operator use, keeps chip and coolant spillage to a minimum and reduces noise. The large doors provide easy access for cleaning and maintenance.

Behringer Saws, Inc., 721 Hemlock Road, Morgantown, PA 19543, 888-234-7464, www.behringersaws.com.