How to Increase Sales in Job Shops and Metal Processing Centers

It’s easy to get caught up in the latest production technology, but sales are the fuel that keeps all of the systems on the shop floor running. To win new sales in the competitive fabrication market, here are three key areas where you can increase your chances to generate more business.

Posted: May 23, 2018

Sales are the lifeblood of any organization, and with hefty investments in people, machinery, facilities and technology, even modest size fabricators need a significant and steady influx of dollars to keep the lights burning. But it’s a competitive world out there, and bringing in new business doesn’t just happen. Let’s take a look at three key areas where you can increase your chances to generate more business:

IT STARTS WITH THE RIGHT PEOPLE (OR NOT)

According to Myers-Briggs, the traits associated with those best suited for sales are: Extraversion, Sensing, Feeling, Judgment . . . or what’s termed ESFJ. You know these people: they are outgoing, energetic, have a positive outlook and are good at multi-tasking. They are likable and trustworthy. But here are a couple of things to consider before you hire the next ESJF that walks in the door.

Independent Reps

Good sales people are hard to find. Moreover, they are expensive and take time to train before they begin producing. Consequently, many shop owners choose to rely on relationships, referrals or on independent representatives rather than hiring a sales staff. Some advantages to this approach are that reps have feet on the street and have already established long-term relationships with a number of potential customers. They generally work strictly on commission and can match a prospect’s need to your metal processing strength. On the flip-side, these companies generally represent multiple clients with a wide array of services and products – probably even a competitor or two of yours. Because of this, the higher commission or easiest sale generally garners their attention. If you choose to rely on independent reps, be sure to take a proactive approach. Keep them apprised of any new processing capabilities or incentives. Stay at the top of their mind. In other words, help them help you.

Direct Sales

The fabrication industry is a relationship-based sales cycle. Potential customers want to work with someone they are comfortable with and can trust. Because of this, most estimators/sales in the fabrication world are industry veterans. They talk-the-talk, walk-the-walk and thoroughly understand the many processes and competitive advantages their shop may have. However, most of these people are Baby-Boomers who are preparing to leave the workforce and hard-to-find Generation X veterans. Let’s face the fact that millennials aren’t exactly knocking down the door to join the industry . . . to combat this, you need to attract new, aggressive, young, sales and estimators. But first, one must understand the unique mindset of this new generation.

Attracting Young Talent

Millennials are hard-working, but they want to have the proper tools. This generation has grown up with technology, understands it, and applies it every day. Unfortunately, while most fabricators have no trouble investing in cutting technology, they don’t give that same attention to a lot of other areas. They have outdated servers, desktops running operating systems from ten years ago, and they don’t have the latest software to design with. Because of this, the best and the brightest shy away from our industry. Attracting fresh talent starts with the tools you are willing to provide them. Focus on how difficult it is to ramp up a new estimator. If you are stuck in the world of spreadsheets, it could take years before someone is capable of quoting/selling off your platform. This industry has amazing technology, but it is often hidden behind a single individual within your shop. The new generation wants to leverage all tools within the fabrication environment, just like the many apps on their phone. This means you must arm them and have them trained on 3D design tools and programming tools to quickly add to their knowledge of the industry.

Finally, when locating talent, focus on those who have an aggressive personality to grow. Some in our industry look at the younger aggressive individuals as “entitled,” or that they haven’t put in their time. The difference is just how independent and resourceful this generation is. Give them the tools, the training, and give them a goal to hit. They might surprise you by just how much they can accomplish in a short period of time.

CREATE OPPORTUNITY FOR OPPORTUNITY

So what’s different about your company? Do you have a clear, compelling advantage . . . or do you just think you do? After all, you have a fiber laser . . . they have a fiber laser. You process sheet metal, plate, and aluminum . . . they process sheet metal, plate, and aluminum. You are “the best” . . . they are “the best.” Instead of falling into the hand-to-hand sales combat conundrum of screaming “Faster!”, “Cheaper!” and “Better!”, why not expand the capabilities of your cutting machines to open the door to new markets? There are plenty of opportunities – with lucrative payback – for those willing to take on the challenge. The stumbling block for many is the willingness to venture outside of their current comfort zone.

Exotic Metals

Because few are willing to tackle these materials, there’s an opportunity for fabricators willing to tackle exotic metals such as stainless steel, brass, copper, titanium, armor plate, tool steel, T-1 steel, nickel, superalloys, platinum and so on – and no special equipment or expertise is required. For the most part, shops that shy away from cutting exotic metals are concerned with damaging machines, ruining costly metals and losing money. This fear is rooted in a lack of experience and exposure to the process. While lasers generally include standard cutting conditions for steel, aluminum, mild steel, and often galvanized metal, few (if any) come with preloaded conditions for exotic metals. Consequently, most shops have neither the experience nor the resources needed to cut exotic metals.

When it comes to cutting exotic metals, most laser operators over-complicate the process. The same variables that are familiar to most operators still apply when cutting exotic metals: focal position, nozzle centering, proper nozzle selection, nozzle gap, assist gas type and pressure, power, frequency, duty and feed rate all influence the piercing, cutting and cut quality of exotic metals just like they do their more common counterparts. It’s always best to crawl before you walk or run, so it’s recommended that first timers cut their teeth with the easier and least expensive exotic metals. Once you have some successes under your belt, move on to the more costly and more difficult materials, like brass, copper, titanium, nickel and platinum.

Coated Metals

Similarly, some fabricators avoid coated materials. What poses a challenge is that, in order to reduce the likelihood of scratches or other damage, these finishes are intended to remain on the materials during processing and shipping. It’s important to learn how to cut coated materials while keeping the protective surface intact. While these finishes certainly do a good job in protecting the material from scratching, they can pose some significant cutting challenges. The objective is to produce quality cuts without removing, scratching, melting or otherwise damaging the coating. The common theme when cutting any coated material or exotic metal is to invest the time to understand the materials you’re cutting and how to best set up your machine for success. It’s vital to take the time to run cutting tests in order to dial-in the machine and establish proper machine cutting conditions.

Finally, remember to utilize the applications department where you purchased your machine. They should be happy to answer your questions and help you to more fully optimize your machine’s capabilities and investment.

New Business AND Higher Margins

When you consider that there are fewer competitors vying for work outside of traditional sheet metal, plate, aluminum, and the fact that most customers will supply the materials, fabricators can attract new business and charge a cutting premium. So don’t be intimidated by venturing outside of your comfort zone. If you’re processing only steel and aluminum with that laser, you’re missing out on a real opportunity. Use that machine tool you invested in to its fullest capability.

DEMOCRATIZE QUOTING

Make no mistake – it’s a war out there. And the biggest obstacle your company faces is generating fast, accurate quotes. Why is this? Until recently, the answer was automation . . . or more precisely, a lack thereof. Take a look at virtually any shop floor and you’ll see automated pallet changing, storage and retrieval systems, even unattended lights-out production. While the production side of the business has steadily evolved, sales and estimation tools have clearly not kept pace. Instead, most shops use antiquated sales tools, such as spreadsheets, production ERP systems, or even good old fashion pen and paper.

Just as some fabricators take advantage of the full capabilities of their machinery to attract business, New Paradigm Laser (Cambridge, ON) does the same thing with their most valuable asset: their people. New Paradigm relies strictly on inside sales to keep machines cutting. The company has a policy to provide quotes to prospective customers in 24 hours or less, but perhaps what’s most impressive is that they rely on inexperienced or even non-sales skilled laborers to generate the quotes. “In this business, timing is everything,” said Marlon Almanza, the plant superintendent at New Paradigm. “The first quote in says a lot about your company’s responsiveness and commitment, and we find that it often leads to winning the job.”

In the past, the company filled sales positions with workers with ten to 15 years of shop floor experience under their belt. Today, thanks to automated quoting, they are able to generate winning quotes with less experienced non-sales workers. “Filling sales positions isn’t a problem,” explained Almanza. “We’re more concerned with finding operators and other skilled laborers than sales people. Our quoting software makes sales quick and simple. We now have the flexibility to reallocate resources from the shop floor or front office to help sell when needed.” Automating the quoting process allows even inexperienced estimators to create winning bids, not just a select few experts.

Automated Estimation & Quoting Software

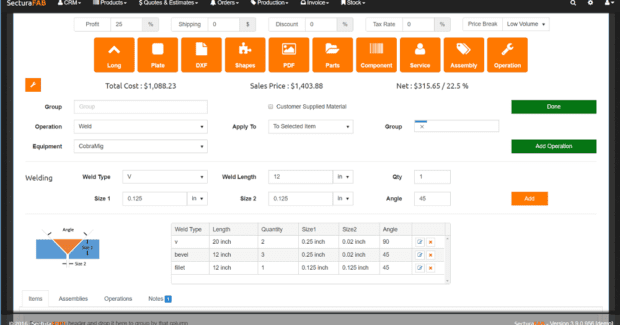

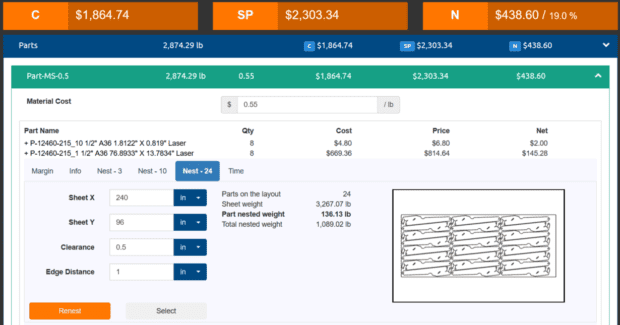

Today, New Paradigm and many other shops are leveraging automated quoting software to increase sales. A leading player in this sector is SecturaSOFT (Cincinnati, OH), which has teamed up with ERP/MRP systems to develop one of the first true sales solutions for fabricators and is one of the first truly mobile platforms that can connect with other software systems in a shop. “Today there is a clamoring from estimators for better, more robust, and more automated tools,” noted Brad Stropes, the chief operating officer of SecturaSOFT and a fabrication industry veteran. “Most current tools rely on a lot of tribal knowledge, require a lot of manual input and duplication of work, and have no real intelligence. We provide an intelligent platform not only to enhance an ERP system, but to replace that old, slow, tough to use spreadsheet.”

Through a development process that focused on users’ experience and their interaction with machine processes, the company has created a powerful system that can easily be used by any individual within an organization: the program utilizes machine intelligence behind a streamlined interface to show the user only what they need to see to quote as efficiently as possible. This is much different than other platforms that require a highly trained fabricator to input all of the machine information one process at a time. The software utilizes intelligent machine calculators to understand what is required by the machine to develop a part.

For example, consider a simple press break operation that can actually become extremely complex: A built-in intelligence understands the requirements of a bend. If a part is a certain length, an additional individual may be needed to hold the part increasing the cost to bend. Also, if a part is too heavy, a crane may be needed to move a part, which increases the cost. Because this intelligence is ingrained into the software, an estimator only needs to input a number of bends, while the software automatically develops the cost per bend.

NOW, LET’S GO SELL!

What does it take to win new sales in today’s competitive fabrication market? It’s easy for shop owners to get caught up in the latest production tools. That’s understandable, because these machines are important to expanding the shop’s capabilities and throughput. But the sales and estimating process is the fuel that keeps those machines running. Boosting sales is a combination of relationships, people, machinery maximized to enable a wide variety of processing options, and equipping your staff with the best tools.

New Paradigm Laser, 33 Raglin Place, Cambridge ON N1R 7J2, 519-623-5222, Fax: 519-623-8633, paradigmlaser.com.

SecturaSOFT, 1776 Mentor Avenue S101, Cincinnati, OH 45212, 513-813-8111, info@secturasoft.com, www.secturasoft.com.