How to Select a Multiaxis Positioning System

The rotary stage multi-axis positioning system from LazerArc consists of a structural frame or simple dial plate that provides an additional rotary axis to a robot.

Posted: May 21, 2018

The number of tasks that can be performed by robots are expected to increase from 10 percent to 25 percent, meaning a much wider variety of systems are available to meet a range of applications, including aerospace, automotive, construction, consumer goods, defense, solar/wind, industrial machines, packaging and more. To achieve lower production cost and improve return on investment, manufacturers are adding custom multiaxis positioning units to their process. For example, with one IEC 61131-3-compliant automation program running on one processor, manufacturers move robots smoothly along on linear track systems while performing several tasks in the same cell.

With these new positioning systems, there is also the ability to adapt a current automation platform to new programs, compared to adding totally new lines. This kind of activity is making automation more cost effective, even for smaller production lines. This means the return on the investment can be achieved faster, even compared to only five years ago. But before getting started down the road to automating some of your production operations, here are two important questions the manufacturing team should ask:

- Have you compared what your ROI would be on an automation system compared to your human labor costs for the same process?

- Are you having a hard time filling jobs that are repetitive or dangerous or that could be carried out by automating it with a robot?

If you answered “yes” to both questions, then you should consider adding custom multi-axis positioning system to your production lines to increase the capabilities of your robots. Depending on your specific application, a custom multi-axis positioning system for manufacturing might include a combination of linear, rotary and slide stages:

- Linear stages are made up of slides that provide accurate and limited positioning along one dimension joined by a guide that contains the motion of the platform. Be sure to discuss with your vendor the different styles of guides as some are better in some applications compared to others. For example, the ILM Transfer System from LazerArc (Troy, MI) moves the tooling to the robots so that they can perform a programmed operation on them. This system can be custom designed and manufactured to fit the user’s application and work within the constraints of their automation facilities. It utilizes a two-way key system that perfectly aligns joined ends, enabling the overall length of a system to be limitless.

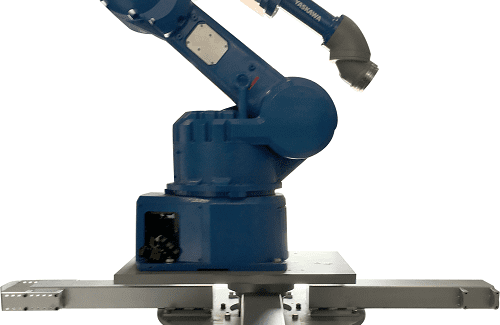

- Rotary stages consist of a structural frame or simple dial plate. Some manufactures offer a rotary stage consisting of a hollow center and stationary robot base to allow for mounting a robot or robots directly above the rotating frame or dial plate. This unique advantage joins the rotary stage and robot together, eliminating the need to mount and level to the floor. This also save on floor space. Rotary stages can be manufactured to accept any robot manufacturer to give that additional rotary axis to your robot.

- Slides: The 7-axis slide function provides an accurate motion and position on the line. Slides are equipped with heavy duty, low-friction linear bearing systems and are most commonly used in automated material handling and welding applications in the aerospace and automotive industries. Custom builds can utilize any robot brand, engineering the system design to match the exact application needs of the end user.

SELECTION CRITERIA

Before selecting a multiaxis positioning system you will need to perform a full analysis of your production process, including:

- Maximum travel of the robot on the line.

- The angles the robot will need to perform the desired processes.

- Payload capacity of current and future products.

- Axis height.

- Bearing types, as they always will need to be selected for the specific application.

- Best actuators to control or move the mechanism or system.

- Correct material (steel, aluminum, etc.) needed to build the equipment to ensure long-term performance.

- Bearings are also an important consideration, as they will increase the performance of a linear, rotary, or slide stages.

Next, choose from a variety of multi-axis positioning systems that are now available for your specific manufacturing production needs based on your earlier responses, such as:

- Single-Axis systems are used in applications where high speed, high acceleration or high accuracy is required. Some options of single-axis positioning systems include rotary index tables, headstock / tailstock, adjustable weld positioner, lift units and tool tray transfers.

- Two-Axis positioning systems typically put the base of the top axis and bolt it to the slide of the lower axis. Two axis systems can be designed to lift/rotate, lift/rollover, sky hooks and move vertically and horizontally.

- Three-Axis systems are used to rotate a part or tooling on one end and at the same time the opposite end can be rotated or safely assessed. A few of the available options include a rotary, trunnions, triple dex satellite, skyhooks, trunnion lift/rotate, and ferris wheel for large parts that can be welded using the flexibility of reorientation.

- Four-Axis / Five-Axis systems improve quality by allowing you to complete a task in a single set up and create multiple and complex shapes without losing the precision. Most applications include sky hooks and five-axis positioners.

- Seven-Axis systems can be manufactured in floor-mounted, elevated or inverted configurations. The advantage of 7-axis robotic slides is that more than one robotic arm can be placed on the same slide for additional productivity and flexibility. They can also be engineered to any length the customer requires. The design incorporates machined keyed ends allowing for sections to be added or removed easily, when repurposing.

LazerArc, 1204 East Maple Road, Troy MI 48083, 877-969-2093, info@lazerarc.com, lazerarc.com.