Metal-Spinning Out-of-Round Engine Lip Skins for Aircraft Engine Housings

These custom machines were built to spin-form lip skins out-of-round by 8½ in to 9 in for the nacelle on the engines of Boeing 737 Max and 777X aircraft. They hold tight tolerances that are verified by thermo-imaging cameras and fed back by the CNC for accuracy tracking and in-process adjustments of the heating torch.

Posted: May 25, 2018

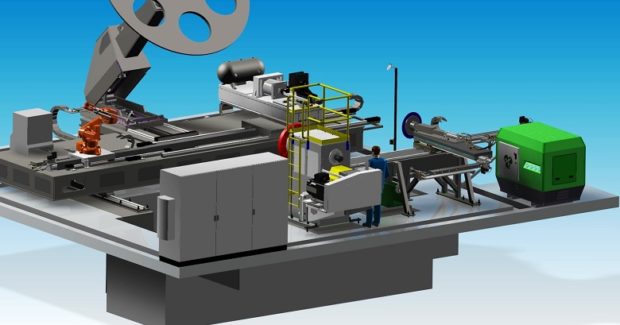

Custom machine tool builder MJC Engineering & Technology, Inc. (Huntington Beach, CA) specializes in metal-spinning machines for sheet spinning, flow forming, wheel spinning and rotary forging applications. They were commissioned to build a series of metal-spinning machines for GKN Aerospace (Redditch, UK) for use at their plants in Camarillo, CA, and Orangeburg, SC. These machines produce lip skins for the engine housings on Boeing 737 Max and 777X aircraft. Using advanced CNC from Siemens Industry, Inc. (Elk Grove Village, IL) and robotic handling technology, plus their own proprietary servopump-controlled Green Power™ hydraulic power unit that saves up to 40 percent on energy, MJC devised a unique system to address an engineering challenge brought to them by GKN: how to spin-form production-run components out-of-round by 8½ in to 9 in from various aluminum alloy blanks measuring up to 270 in diameters and 5/8 in thickness, while holding tight tolerances to be verified by thermo-imaging cameras and fed back by the CNC for accuracy tracking, plus integrate the heating torch for in-process adjustments.

Carl Lorentzen, the president of MJC Engineering, Per Carlson, their vice president and general manager, and Don Hebert, an electrical engineer, were up to the task: they combined the same metal-forming process that has been around for millennia with modern CNC controls and robotics to create a state-of-the-art manufacturing process used to produce laminar flow lip skins, which are highly engineered aerodynamic structures that make up the leading edge of jet engine nacelles. Metal-spinning is a forming process in which a blank of material is rotated on a spinning machine similar to a lathe. The blank of material is clamped onto a spin-forming mandrel and rotated by servo-controlled motors and drives. During rotation, heat is applied by a gas torch affixed to a robotic armature and a roller on the spinning machine makes contact with the part blank, forcing the part blank to flow over the spin-forming mandrel surface.

Spin-forming has the ability to form very large and thick plates quickly and accurately like no other metal forming process. Though highly efficient in operation, the 737 Max and 777X CNC metal-spinning machines rely upon the precise and consistent application of heat throughout the metal forming cycle. Even the slightest variation in heating will contribute to undesirable results in the formed part. Until recently, manufacture of these lip skin components relied upon human intervention to control the direct application of heat throughout the spin-forming cycle. While this method can certainly produce a functional part, the associated variations in part consistency created downstream difficulties and challenges in subsequent fabrication and assembly operations. In the past, lip skins were produced by other methods, including draw-forming, bulge-forming and drop-hammering. The spin-forming and machining techniques now used at GKN have reduced overall manufacturing time and tooling costs, while improving part consistency.

To reduce variation in the CNC spin-forming process, GKN Camarillo joined forces with MJC to create an automated CNC system consisting of robots that apply heat in a precise and absolutely consistent manner, tied directly to a program that shapes the part. This careful interplay between the heating and spin-forming operations is made possible by a Sinumerik 840D sl CNC that “integrates and monitors every movement between the spinning machine controller and the heating robot controller, resulting in a smooth flowing production scenario with perfect timing and high marks for efficiency,” said James O’Sullivan, the general manager of GKN.

Before this combination, variation in product output was much less predictable. But now part heating difficulties and variations are a thing of the past: “CNC spin-formed lip skins with automated robotic heating exit the process as consistently as a stack of quarters, to draw an analogy,” stated Carlson. “The results are no less than phenomenal, yet are derived from straightforward mathematical computations made possible by modern CNC technology. There’s real power here. Let’s face it, everyone knows that variation is the number one contributor to low manufacturing yields and increased operating costs. Study your process, understand where variations occur and then eliminate them with cost-effective solutions. The improvement literally catapults a production floor to new levels of manufacturing excellence. It certainly has at GKN.”

In operation, the spinning machine takes the overhead crane-loaded 270 in diameter blank, fixes it to the tailstock of the machine and rotates it on a 150 hp motor-driven spindle, then progressively applies heat via the gas torch on the robot arm. Raytek thermal imaging cameras closely monitor the heat readings over the entire surface to create multiple control cones. When inconsistencies are detected, the heat is appropriately adjusted in real time by the controllers. The heated material is then formed over the mandrel into the desired size, with typical out-of-round conditions ranging from 8½ in to 9 in. Simatic S7 PLC technology is onboard the spinning machine, controlling the various mechanisms while the CNC integrates and feeds back all data. Solid Edge CAD software is used for the design of the lip skin, while Siemens NX CAM translates the design data into machine execution steps. Each spinning machine also incorporates Sinamics drives and Simotics motors from Siemens.

“There are seven axes of motion controlled by the CNC,” explained Hebert. “We created custom screens for teach-in and playback on the machine to facilitate faster commissioning and troubleshooting onsite for the operators. Zone Pro and Spin CAD were used to create the tool paths. On the robot, there are 32 pre-programmed moves, fully integrated with the heating and thermal imaging processes. The robot runs with an external PLC through G-code on the CNC, which dictates the on/off heating and cooling controls based upon feedback from the temp zones monitored.” Carlson added, “From the time we built the first machine for Camarillo to the later machine in Orangeburg, we have since transitioned to newer technology. That’s how fast things are moving.”

MJC Engineering & Technology, Inc., 15701 Container Lane, Huntington Beach, CA 92649, 714-890-0618, Fax: 714-895-3561, clorentzen@mjcengineering.com, www.mjcengineering.com.