Vibration and Chatter Issues? Don’t Overlook This “Light Bulb” Moment

Suppliers of CNC machining centers, toolholders and cutting tools are increasingly urging OEMs, contract manufacturers and job shops that machine complex aerospace parts to add an overlooked, yet critical component that can prevent vibration and chatter issues – as well as the incorrect assignment of blame for causing the problems.

Posted: May 21, 2018

Manufacturers and distributors of horizontal and vertical machining centers, cutting tools and toolholders spend years establishing strong relationships with customers by providing top quality, precision equipment. Sadly, these relationships can easily be undone by a small, overlooked part that costs less than $30: the retention knob – a critical component in the machining process. In fact, the problem is so prevalent in CNC equipment that uses drawbars to hold tapered toolholders securely in the spindle that many are adopting a policy of only selling the High Torque retention knob or, at minimum, strongly urging machine shops to invest a few dollars more for an item they do not even sell. After all, many suppliers have already discovered a hard truth: when machinists experience vibration, chatter and fretting after purchasing equipment, they tend to blame the new spindle, toolholder or high-end carbide cutting tool, despite the fact that improper seating of the toolholder due to poorly designed traditional retention knobs is more likely the cause.

When this occurs, it reflects poorly on the supplier and can cost them considerable short-term and repeat business. This is the real-world reason why JTEKT Toyoda Americas Corporation (Arlington Heights, IL) regularly recommends High Torque retention knobs for use on their vertical and horizontal machining centers. “If the cutting conditions are poor, the customer immediately assigns blame to the machine,” explains Craig Gilsinger, the applications/quality manager for JTEKT Toyoda Americas. “So we regularly recommend [the High Torque retention knob] to them. It not only ensures our equipment will cut better, but also that we won’t get blamed for machining issues when the machinery is not the cause.”

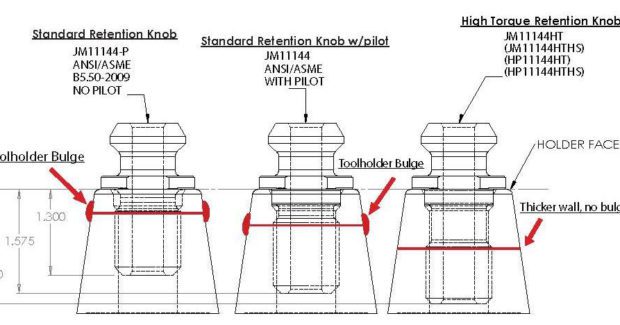

Gilsinger notes that, more often than not, investigations of vibration and chatter issues point to improper seating of the toolholder in the spindle because when a standard retention knob is tightened, it can produce a bulge in the taper that prevents full contact and correct seating in the spindle. As a result, the toolholder is unable to pull completely into the spindle and, subsequently, cannot make contact with up to 70 percent of its surface. “We have seen many situations where retention knobs have been overtightened,” he says. “A guy goes to the workbench and uses a wrench and a hammer to tighten the retention knob, a method which is certainly not to the proper torque. This ends up distorting the taper so the tool does not seat in the taper correctly.” This can cause a multitude of problems that too often get blamed on the equipment: vibration and chatter, poor tolerances, non-repeatability, poor finishes, shortened tool life, excessive spindle wear and tear, run-out and shallow depths of cuts.

Surprisingly, this known design flaw with its far-reaching consequences is often overlooked or even dismissed. So when JTEKT Toyoda Americas learned about the High Torque retention knob offered by JM Performance Products, Inc. (JMPP; Fairport Harbor, OH), they quickly decided to recommend it with each machining center purchase, as well as on their full turnkey systems. The High Torque retention knob is designed with a longer reach so that it threads deeper into the threaded bore of the toolholder. Consequently, all thread engagement happens in an area of the toolholder where there is a denser cross-section of material to counter deformation. The knob also features a precision pilot and is balanced by design to increase rigidity. To guard against a High Torque retention knob being over-tightened, which can still produce a bulge, JMPP provides specifically-calculated torque specs based on drawbar pressure.

By combining this retention knob with the proper torque, spindle contact with the taper is improved to close to 100 percent every time, which drastically reduces vibration and chatter. These retention knobs work with all existing toolholders, including BT, DIN, ISO, and CAT toolholders from 30 taper to 60 taper. For Dan Carlstrom of Carlstrom Associates, LLC (Columbus, OH), a manufacturer’s rep organization that sells toolholders, milling tools and workholding systems, the “light bulb” moment came when he recommended the High Torque retention knob to a shop that was struggling with a boring tool he had sold them. “The customer was having a problem holding size on a component, so they had to take multiple passes and then do a final reaming pass to get this hole to size,” he recalled. “When they put the High Torque retention knob on the toolholder, the boring tool was able to cut the hole to size, in tolerance, in one pass. They never gave me total cost savings, but needless to say it was significant. It also solved a huge headache for them.”

Carlstrom emphasizes that his company does not represent or sell JMPP High Torque retention knobs, but adds that whenever he runs a test of his tooling for a customer, he does so with the knob installed to eliminate poor seating in the spindle as a variable that could affect performance. “When I run an end mill test, a toolholder test, or a boring bar test, I will not run it without a High Torque retention knob, period,” he says. “I know it will make my tools – which I get paid for – run properly.” By recommending or supplying these retention knobs, suppliers can also earn the respect and gratitude of their customers, in turn resulting in increased loyalty and referrals, all of which provides them with a competitive edge.

JM Performance Products, Inc., 1234 High Street, Fairport Harbor, OH 44077, 440-357-1234, Fax: 440-357-1129, sales@jmppinc.com, www.jmperformanceproducts.com.

JTEKT Toyoda Americas Corporation, 316 W. University Drive, Arlington Heights, IL 60004, 847-253-0340, Fax: 847-253-0540, info@toyoda.com, www.toyodausa.com/machines.

Carlstrom Associates, LLC, 3034 Scioto Place, Columbus, OH 43221, 614-679-1924, www.carlstromassociates.com.