Why and How to Break-In Band Saw Blades

Virtually all manufacturers agree that a blade that has been properly broken-in will have a significantly increased service life. So why would this important step be skipped over?

Posted: May 29, 2018

In today’s competitive environment, everyone is on the lookout for ways make their business operations more profitable. Sometimes simply cutting costs can seem like an attractive way to reach this goal. However, simply reducing the cost of equipment or a process is not a guarantee of success. A better goal is to become more efficient on the job so that operations are more productive, ultimately improving the bottom line. In the context of band saw cutting operations, high efficiency and productivity means keeping the saw running. Downtime associated with blade changes due to wear or breakage is closely monitored. A considerable amount of time and energy goes into finding ways to reduce downtime. Shops are always looking for a band saw blade that will last longer and deliver better quality cuts. While cost is important, it is the cost per cut that really matters. Using a band saw blade that lasts longer while making high quality cuts minimizes the cost per cut and directly correlates to increased productivity.

The service life of a band saw blade and the quality of the surface finish made by the cut are not solely determined by the blade manufacturer’s product design. Machine maintenance and operating practices can contribute to, or detract from, this performance. Assuming that the band saw is well maintained and that the operator follows the speed and feed settings recommended by the manufacturer, there is still one more critical step that all too often is skipped: breaking-in the blade. Virtually all manufacturers agree that a blade that has been properly broken-in will have a significantly increased service life. So why would this important step be skipped over? Some feel it is not worthwhile to slow down the cutting operation to break-in a blade. But though the break-in process does involve reducing the feed pressure for the first 25-100 sq in of cutting, the extra time is compensated many times over in the extended life span of the blade, in addition to the improved surface finish results in the cuts.

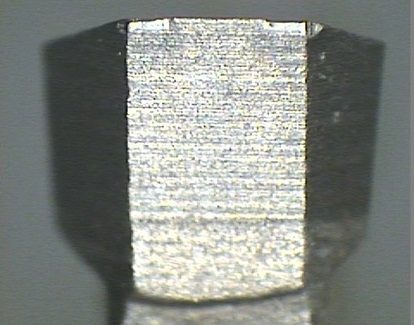

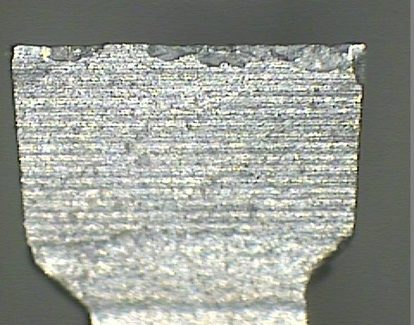

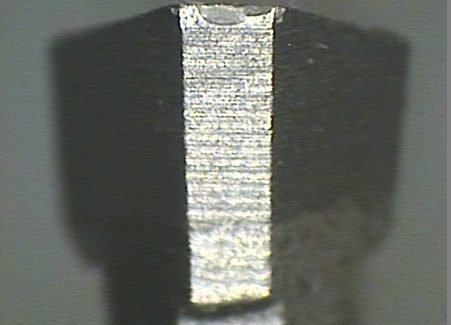

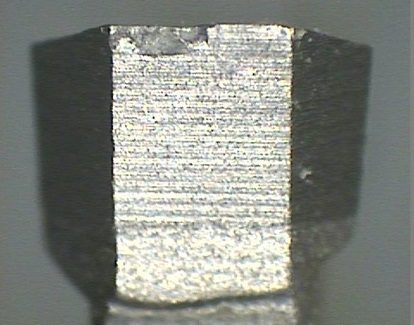

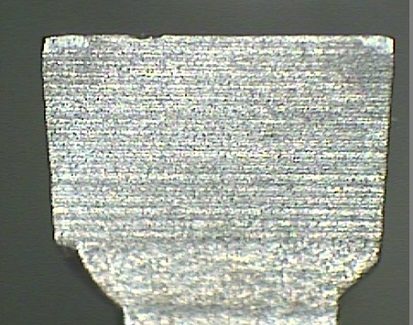

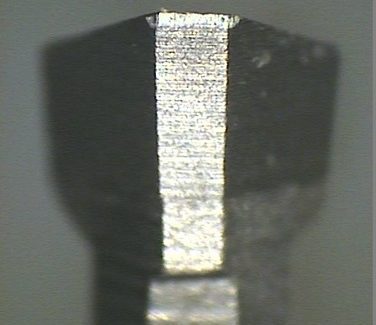

BREAK-IN VISUALIZED

What does breaking-in a blade actually do? New band saw blades have very sharp edges on the teeth. That very sharp edge is easily broken and chipped if not broken in properly. Just like a very sharp pencil, the sharp point can break off when you start using it, leaving an irregular, jagged point that doesn’t write well. By gradually increasing the feed pressure during break-in, the sharp tooth edge is evenly honed, leaving a very fine radius to the leading edge of the tooth. This radius allows the chip to shear away from the workpiece more readily and also gives the required support to the tooth tip, which undergoes extreme forces in the cutting process.

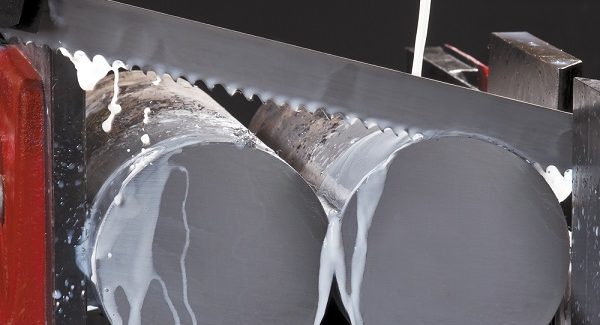

BREAK-IN PROCESS

The process to break-in a band saw blade will vary depending on the characteristics of the material being cut. While breaking-in a blade, have the machine running at the normal surface feet per minute (SFPM). For softer materials, such as carbon steel and aluminum, adjust the feed pressure to 50 percent of the normal cutting rate for the first 50-100 sq in, then gradually increase the feed pressure to 100 percent cutting rate. For harder materials, such as nickel-based alloys including Inconel, or other difficult materials such as hardened steels, tool steels and stainless steels, adjust the feed pressure to 75 percent of the normal cutting rate for 25-75 sq in. Gradually increase the cutting rate to reach 100 percent after 50 sq in. As the feed pressure is increased to the 100 percent cutting rate, be careful to avoid creating vibrations that can occur by increasing the rate too quickly.

Once the teeth are honed and properly broken in, the blade will cut faster, straighter and last longer than an incorrectly broken-in blade. Following a proper break-in process is a simple, easy way to ensure that you’re getting the maximum productivity in your sawing operation.

The L.S. Starrett Company, 121 Crescent Street, Athol, MA 01331, 978-249-3551 ext. 580, www.starrett.com.