Why Invest in a Tapping Tool?

Though there are less expensive methods for adding threads to sheet metal parts, in-punch tapping is far and away the fastest, most accurate way to produce threads. Ultimately, the decision comes down to the thread type, specification and how many tapped holes are needed.

Posted: May 20, 2018

If you are producing sheet metal parts on a punch press, it’s likely you are also incorporating threads into those parts. In-punch tapping is far and away the fastest, most accurate way to produce threads. However, tapping tools come at a price. Here we explore the benefits of tapping tools compared with other methods for adding threads. You may wonder why, if there are less expensive methods for adding threads to sheet metal parts, fabricators should consider investing in a tapping tool. Ultimately, the decision comes down to the thread type, specification and how many tapped holes are needed.

MANUAL TAPPING

More often than not, when the need to produce threads on a part arises, precision metal fabricators use a drill press or other manual process to add the thread, after the punching operation is complete. While relatively inexpensive, this method of tapping threads requires additional part handling and labor that slows the entire fabrication process and increases production costs. It can also be unstable and imprecise, which adds to the risk of injury or scrapped parts.

THREADED METAL CLIPS

Another common method of adding threads to a sheet metal part is to use a threaded clip that clips onto the sheet metal at a specified location. Using clips still requires operators to punch a hole in the part, and then a secondary operation is needed to manually attach the clip. Unfortunately, adding a clip creates only one thread that is not as strong as a tapped hole. Clips are also somewhat limited by material thickness and sheet placement. The cost of this method is roughly $0.50 per clip, plus labor.

THREAD FORMS

Thread forms can also be quickly produced in the punch press using a forming tool to form a thread with no manual steps. Like a tapping tool, thread forms can create a thread anywhere on the sheet accurately. While they are more popular than threaded metal clips, thread forms only create a single thread, which means they don’t have near the holding strength that a tapped hole does. This limits the applications they can be used for depending on torque requirements.

Each of these methods for adding threads to parts has their place when fabricators are looking for a low-cost solution to produce a smaller volume of threaded holes.

TAPPING TOOLS SATISFY A NEED FOR SPEED

When you need to produce a higher than average number of tapped holes, tapping tools save time and provide the accuracy that’s lost with secondary threading operations such as those described above. A tapping tool makes it possible to quickly and easily tap holes on the punch press and eliminate the need for a secondary tapping operation. This method of in-punch tapping not only boosts productivity, but can significantly lower your cost per piece over conventional manual tapping methods. Tapping holes on the punch press is the fastest, most accurate way to add threads to your parts. Fabricators are able to tap a hole with every machine stroke – up to 200 holes per minute, depending on material type and thickness. When compared to manual tapping methods that allow less than a dozen tapped holes per minute, tapping tools deliver remarkable improvements to speed and performance.

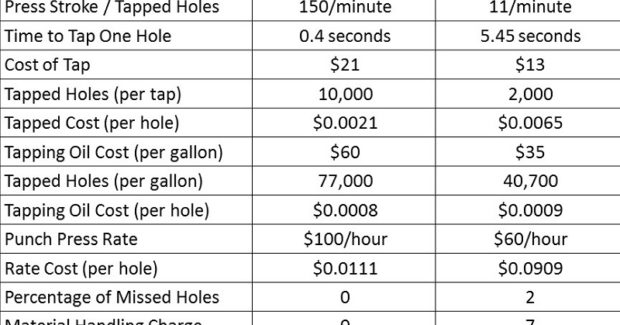

The nearby chart is a side-by-side comparison of hole tapping using our QuickTap™ tapping tool in a punch press vs. manual tapping methods. The cost savings per piece with the tapping tool are clear. Using a tapping tool in a punch press also produces higher quality threads: the ability to program the exact location of tapped holes on the sheet ensures the accuracy of your threads part after part. Tapped holes are also stronger than threads produced using metal clips or thread forms. When compared to lower cost, less effective methods of adding threads to sheet metal parts, there’s no question that for higher volume applications, tapping tools provide a significantly higher value per piece by eliminating secondary operations, increasing productivity and improving thread quality.