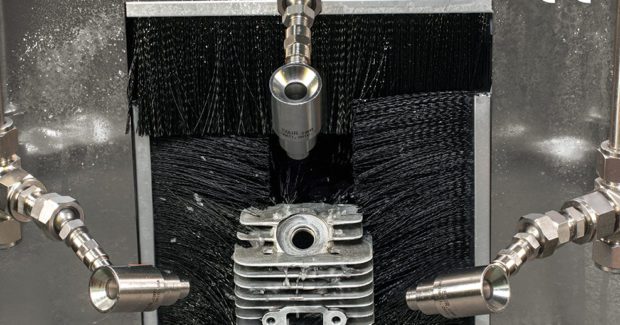

Stainless Steel Air Jets Resist Corrosion & Heat

For reliable and efficient blowoff and cleaning in corrosive, high temperature or washdown environments up to 400 deg F, 303SS Air Jets from Exair replace open tubes and pipe nipples on parts cleaning, drying and cooling operations to produce up to 1.25 lb of force upon the target.

Posted: June 4, 2018

New 303SS Air Jets from Exair Corporation (Cincinnati, OH) provide reliable and efficient blowoff and cleaning within corrosive, high temperature or washdown environments. These 1/8 NPT Stainless Steel Air Jets replace open tubes and pipe nipples on parts cleaning, drying and cooling operations. With temperature rated up to 400 deg F, they will produce up to 1.25 lb of force upon your target. Available in two styles, the High Velocity Air Jet provides maximum force with a confined and directed airstream. The Adjustable Air Jet style allows you to easily control the air upon your target with its micrometer air gap indicator. These Air Jets utilize the Coanda effect to pull in the surrounding ambient air and increase the total volume of air impacting your target area. Both the outlet and inlet can be ducted for remote positioning.

Air Jets require a small amount of compressed air which can be less than half that of open air lines in your plant. Typical noise level reductions are 8 dBA to 10 dBA. Stainless Steel Air Jets complement a complete line of engineered air nozzles that reduce energy use and noise levels while increasing safety. All of these Air Jets and Nozzles meet OSHA static pressure requirements and CE safety standards.

Exair Corporation, 11510 Goldcoast Drive, Cincinnati, OH 45249-1621, 800-903-9247, Fax: 513-671-3363, techelp@exair.com, www.exair.com/118/ssaj.htm.