Advanced Metalworking Equipment to Increase the Bottom Line

For processing heavy materials, structural profiles, non-ferrous material and more, the latest hydraulic ironworkers and sawing systems from Scotchman provide the flexibility and precision needed for high productivity on tough jobs.

Posted: July 16, 2018

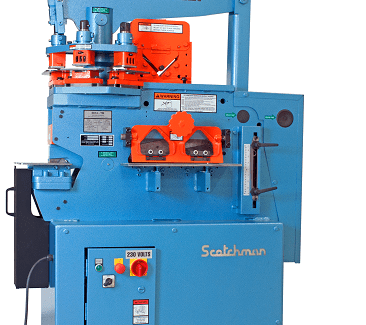

In Booth N-236408, Scotchman® Industries, Inc. (Philip, SD) will demonstrate their latest 50-ton hydraulic ironworker: the improved 5014-ET ironworker has taken the 5014-TM, 3-station turret model to a whole new level. This new 50-ton ironworker now comes standard with a new, improved electric stroke control that makes this machine more precise than ever. Upgrading this 5014-ET ironworker to a fully electric stroke control increases its accuracy and reduces the mechanical linkage which extends the life of the machine. Bending parts on this 50-ton is now as accurate as any other ironworker in the industry and is backed by a Best-in-the-Business warranty. The 5014 ET is made in America with many standard features and equipment, including an angle shear that will shear up to 4 in x 4 in x 3/8 in angle iron and a flat bar shear that can shear ¾ in x 4 in to ¼ in x 14 in. The new electric stroke control with remote foot pedal and punch slug receptacle are standard features at the same affordable price as the 5014-TM model.

This machine also features a rectangle notcher that will notch up to 2-1/2 in x 3 in on 5/16 in thick material. With its component tool table design, it has the ability to accept optional equipment, such as a 12 in press brake, rod shear, square tube shear, picket tools, pipe notcher, and special tooling, which is also available.

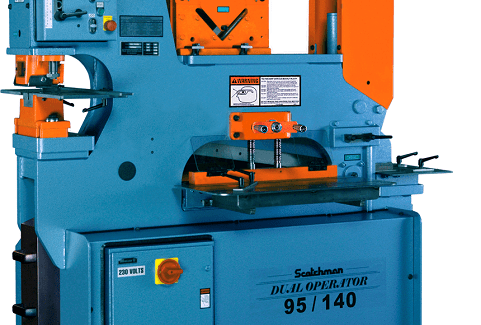

Also on display will be the Dual Operator 95 Ton Hydraulic Ironworker that has a hydraulic system designed with two pumps, allowing two operators to use the machine at the same time and ensure that both operations have full hydraulic pressure and speed. This ironworker comes complete with two valves, two stroke controls and two remote foot pedals. The DO 95 has a 95 ton capacity punch and a 9 in throat depth that can punch a 1-3/16 in hole on 1 in thick material. It complements the existing dual operator machine line, which consists of dual operator ironworkers with punch capacity ranging from 70 tons to 150 tons. This American-made ironworker, with four built-in stations, offers versatile, flexible and dependable features. Standard features include a 6 in x 6 in x ½ in angle shear and a rectangular notcher that can notch 3 in x 4 in x ½ in material. The 24 in flat bar shear features a low rake angle and has the ability to shear up to 1 in x 8 in and 3/8 in x 24 in material. The DO 95/140-24M now comes with a three-year warranty. This machine also has the ability to accept optional equipment such as press brakes, rod shear, tube shears, picket tools, as well as special tooling.

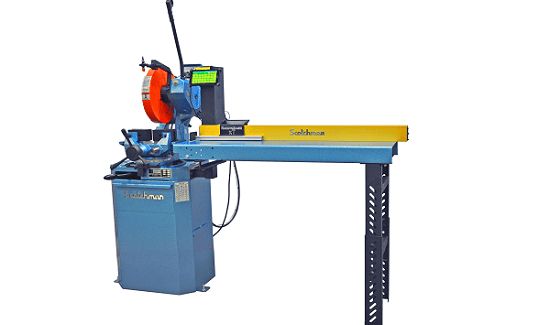

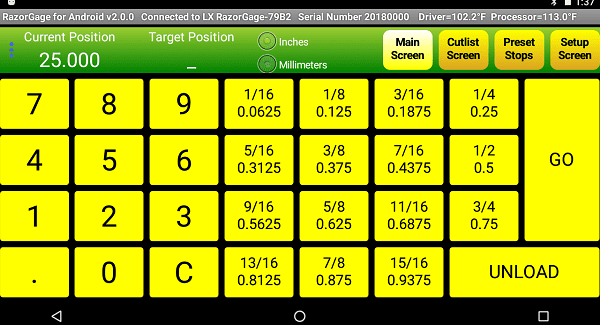

Also on display will be the RG Digital Quick-Stop coupled with a CPO 350 cold saw that turns a manual machine into a part cutting workhorse with repeatable accuracy. The saw and programmable measuring system are both American-made and work together seamlessly to increase production while reducing scrap and operator error in the shop. It is also easy for any operator to enter cut lists into the controller and make accurate cuts every time. The CPO 350 is an industrial grade circular cold saw with 100 deg of mitering ability, a dual clamping self-centering vise, chip drawer and more. This saw has a two-speed motor and utilizes up to a 14 in diameter blade, giving it a 4-7/8 in OD round capacity that consistently produces burr-free, high quality cuts. It is backed by a three-year warranty. Increase production and deliver reliable stop position accuracy of ±.008 in by coupling this saw with an RG Digital Quick-Stop measuring system. Operators can change lengths in a snap by using preset hotkeys and easily adjust measurements on the 7 in touchscreen Android tablet. Or upload an entire cut list using its Bluetooth and Wi-Fi capabilities.

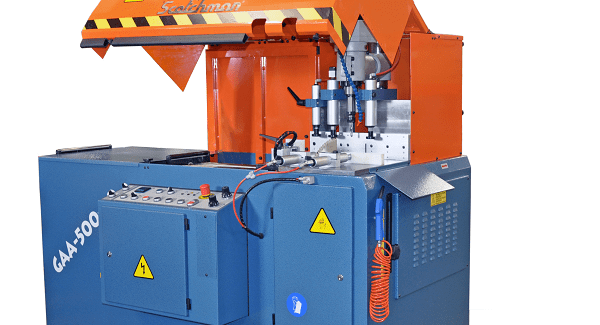

Also on display will be the Drill Tap option for the GAA-500 90 Automatic Upcut Circular Cold Saw, the newest addition to their non-ferrous saw line with more features and possibilities than ever before. The GAA-500 90 is a large capacity upcut automatic saw for cutting non-ferrous materials at 90 deg up to 6 in square and round. The saw uses a shuttle feed design with an adjustable vertical and horizontal clamp system to fit almost any profile. Standard features include a 7.5 hp motor that delivers a cutting speed of 3,000 rpm, pneumatic mist coolant system, and a base designed with two chip extraction ports. The rotary dial allows for fast and easy length adjustments and part lengths are easily held to the length tolerance of ±.006 in per index. Adding the DT-20 (Drill/Tap 20mm) option to the GAA saw creates a true production saw with the ability to drill and tap holes up to 20 mm with a single spindle drill, or drill multiple holes at one time by adding a multi-spindle drill.

Make thousands of clips fast with the GAA-500-90 DT20. By adding a CNC option along with the DT option, an operator can position a hole or set of holes on a single axis on the piece, then cut to length. This CNC saw has a 30-part storage capacity with ten different programs available for each stored part. Each program has space for 30 different jobs – complete a whole day’s work with this one saw. The GAA-500-90 saw is available in 230 volt and 460 volt configurations and is backed by a Best-in-the-Business two-year warranty.

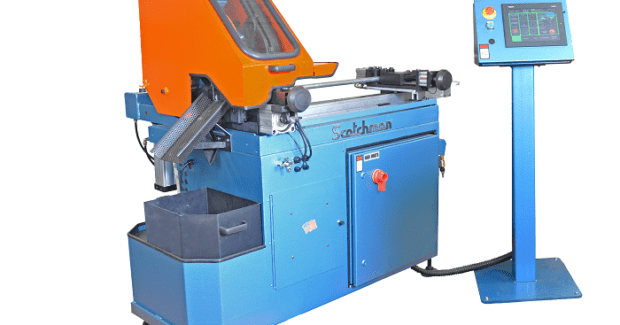

Also on display will be the fully programmable CPO 315 HFA-CNC saw for fast and accurate cut lengths. It uses a 30 in linear actuator driven by a servo motor. Its 315 mm blade cuts up to 3-1/2 in diameter tubes or pipe and up to 1-3/4 in solid material while maintaining a length tolerance of ±.006 in per index and a squareness tolerance of ±.002 in per diameter. The standard CPO 315 HFA-CNC features include a large 10 in touch-screen control, an unlimited length setting with a 30 in single length shuttle, and a variable speed control. The setup to change to a different part length only takes a few seconds, and the first part cut is always accurate. This saw has the ability to program to a set length with a number of pieces to cut, or enter up to four separate lengths and amounts to be cut in sequence. This American-made machine is available in 230 volt and 460 volt configurations and is backed by a Best-in-the-Business two-year warranty.

Also being showcased will be the SUP 600 NF Upcut Circular Cold Saw designed specifically for cutting non-ferrous material. Featuring a 24 in (600 mm), 132-tooth carbide blade that is capable of producing round cuts up to 8 in diameter and rectangular cuts up to 15 in x 6 in, the SUP-600 NF offers an increased cutting capacity not found in traditional pivot down saws. When coupled with an AngleMaster digital material positioning system, this upcut saw creates a semi-automatic programmable saw system that automatically rotates to any cut angle, pushes material into the saw, automatically rotates to the next desired angle, and produces a completely finished part. Cut lists can be stored on its 21 in touch-screen control. This is a must-see for the aluminum extrusion market. Standard features include an adjustable feed rate, mitering capability with fixed stops at 22.5 deg, 45 deg, 90 deg, -45 deg, and -22.5 deg, two horizontal and two vertical pneumatic clamps to secure material being cut, a 4-1/2 in port for chip collection, plus a drawer under the bottom of the saw. The SUP-600 NF is available in 230 volt and 460 volt configurations and is backed by a superior warranty.

Scotchman Industries, Inc., 180 East US Highway 14, PO Box 850, Philip, SD 57567, 605-859-2542, Fax: 605-859-2499, www.scotchman.com.