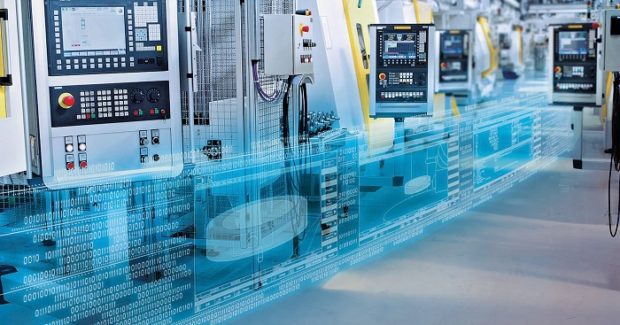

Moving Machine Builders and Users Toward the Digital Factory

The Mindsphere IoT operating system from Siemens is an open, customized platform for recording and analyzing large volumes of real-time, plant-wide production data used to operate, manage, program and maintain machine tools on the shop floor.

Posted: July 10, 2018

In Booths E-134500 and E-134502, Siemens Industry, Inc. (Elk Grove Village, IL) will display their Sinumerik CNC hardware and software systems that offer dual tracks for the machine tool builder and end-user attendees from job shops and production departments of all types. Advancements in machine tool automation will be demonstrated for various CNC machines: from basic milling and turning applications to multi-axis machining centers and fully automated, flexible work cells used throughout the manufacturing industry. Also on display will be the new Mindsphere “software as a service” concept that enables machine tool users to gather, prioritize and access data in real-time using cutting edge technology. Reflecting the drive to the digital factory, a virtual experience for machine tool design and build functions will be presented to the OEMs, while end-users will experience how the machine tools used on their shop floors will be operated, managed, programmed and maintained in the future.

Mindsphere is a major step on the road to digitalization and Industry 4.0, offering machine tool builders and end-users alike a variety of customizable software and application options for the control and maintenance of their operations. It is an open IoT operating system that allows a customized platform for recording and analyzing large volumes of plant-wide production data. A user can interact with Siemens to devise a variety of MindApps for machine tool predictive maintenance services, energy data management and even resource optimization development. In combination with advanced motion control technologies and PLM services, the full process chain from CAD to CAM to virtual simulation to production and performance assessment will be on display. Machine tool builders will see an entire portfolio of CNCs, plus the integration of robotic machining and systems for additive, in tandem with the advanced automation scenarios of today’s manufacturing environment.

Siemens Industry Inc., 390 Kent Avenue, Elk Grove Village, IL 60007, 847-640-1595, Fax: 847-437-0784, www.usa.siemens.com/cnc.