Ultrafast Rapid Prototyping and On-Demand Production

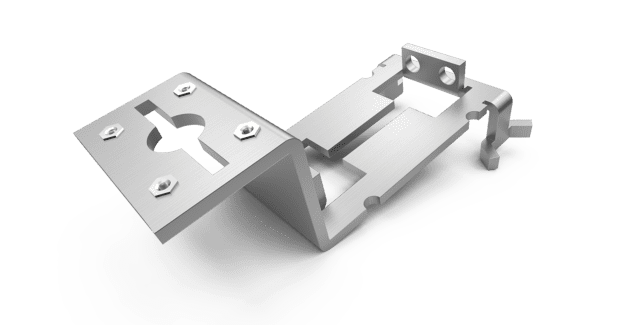

With automated 3D printing, CNC machining, sheet metal fabrication and injection molding processes, Protolabs uses digital manufacturing to be one of the fastest sources for rapid prototyping and on-demand production.

Posted: July 7, 2018

In Booth N-432327, Protolabs (Maple Plain, MN) will display their capabilities as one of the fastest digital manufacturing sources for rapid prototyping and on-demand production, capable of producing technology-enabled custom parts and assemblies in as fast as one day with automated 3D printing, CNC machining, sheet metal fabrication and injection molding processes. Their digital approach to manufacturing accelerates time to market, reduces development and production costs, and minimizes risk throughout the product life cycle. In December 2017, Protolabs acquired custom parts supplier Rapid Manufacturing Group, LLC (Nashua, NH) for $120 million to offer another quick-turn manufacturing service while expanding their own CNC machining capabilities. This further optimized their product development and improved their supply chain efficiencies through a variety of digital manufacturing methods. With revenue of $45 million, Rapid specializes in quick-turn sheet metal fabrication and CNC machining and employs approximately 300 people, expanding the Protolabs team to more than 2,000 employees worldwide.

Protolabs, 5540 Pioneer Creek Drive, Maple Plain, MN 55359, 887-479-3680, Fax: 763-479-2679, www.protolabs.com.