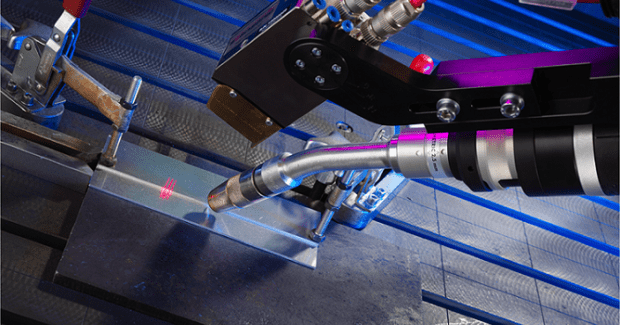

Optical Seam Tracker for Robotics and Hard Automation

The 3-line Optical Seam Tracker TH6x from Abicor Binzel uses advanced laser line technology to track the joint in real-time and guide the torch perfectly through the weld joint and create the perfect seam.

Posted: August 23, 2018

Weld throughput and reduced scrap are the challenges any welding operation deals with on a daily basis. In Booth C-12328, Abicor Binzel USA, Inc. (Frederick, MD) will display their 3-line Optical Seam Tracker TH6x that uses advanced laser line technology to track the joint in real-time and guide the torch perfectly through the weld joint and create the perfect seam. Perfectly suited for robotics and hard automation, TH6x laser line technology is unique in its triple beam sampling to ensure the most accurate joint reading possible, and it performance especially well on reflective surfaces including aluminum, stainless steel, and diamond plate. The Zero Gap Optical Seam Tracking system TH6i can also track the difficult to weld and program zero gap joints accurately and with no pre-scanning required – including on reflective surfaces. The TH6x graphical user interface (also known as GUI) pre-loads the classic joint types for easier programming of the seam tracker to the joint. With a processor that runs independent of the seam tracking hardware, the TH6x runs cooler and it most cost-effective than other seam trackers on the market.

Abicor Binzel USA, Inc., 650 Medimmune Court, Suite 110, Frederick, MD 21703-2602, 301-846-4196, www.binzel-abicor.com.