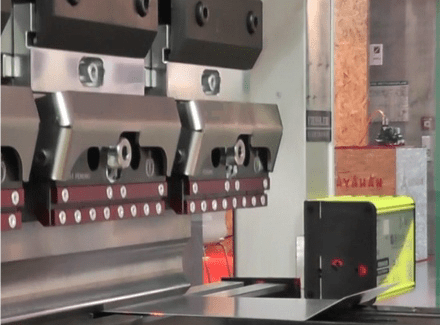

Press Brake Safety System for High Speed Operation up to the Clamp Point

The Fiessler Elektronik AKAS 3P press brake safety system from Press Brake Safety creates a 3D laser safety field underneath the bending punch that prevents pinching or crushing of finger or hand, with no reduction in productivity during the entire closing movement.

Posted: August 31, 2018

In Booth B-6666, Press Brake Safety (Zionsville, IN) will feature the productive, safe and user friendly AKAS® 3P press brake safety system from Fiessler Elektronik (Esslingen, Germany) that performs high speed operation up to the clamp point. Characterized by maximum productivity and safety, this safety system makes it possible to close the press brake safely up to the clamping point in high speed in the flat bending mode. During the entire closing movement, the operator is safely guarded by a 3D laser safety field underneath the bending punch that prevents pinching or crushing of finger or hand, with no reduction in productivity. This system guarantees full safety in flat and box bending mode and is TÜV CE type-approved, UL-listed, and complies with EN12622, B11.3, Z142 and NR12 standards.

AKAS 3P transmitters and receivers are supplied with fully automatic electromotive supports to ensure that necessary adjustments after a tool change are possible without any loss of time for tools of different heights. Simply press the setting start button to trigger the setting procedure. Other required adjustment time can be used for tasks such as providing the material or programming machine parameters.

Press Brake Safety, 1938 South 925 East, Zionsville, IN 46077, 800-901-1193, www.pressbrakesafety.com.