Connective Forms Make Fastening Faster

Incorporating connective forms into your existing fabrication assembly process adds functionality to sheet metal components in the place of conventional fastening methods. Available for most styles of punch press, connective forming tools remove secondary welding, fasting and clipping operations to reduce assembly time and produce valuable cost savings.

Posted: September 21, 2018

Fabricators who fasten sheet metal components together to create cabinet assemblies for products such as appliances, storage cabinets, HVAC equipment and more are always looking for ways to maximize efficiency and manage their cost of goods sold (COGS). Conventional fastening methods, such as screws, spot welding or hardware fastener clips, can require a substantial amount of labor during assembly that can be time consuming and costly. One way to save time and money in your assembly process is to use common punch forming tools in a different way: punch forms can be used to manufacture fasteners right into the components themselves to save assembly time and reduce costs. In some cases, you may be able to use punch tools that are already in your shop. Common punch forms, such as louver tools, half shears, and extrusions, can all be used to manufacture fasteners right into the components themselves. These tools make it possible to quickly and easily snap parts into place.

When using these punching forms to create connectors, one component will typically have the connective form and the second will have a pierced hole that will slide over the form and lock in place to complete the assembly. Louver tools are typically used to create ventilation, but when mated with a pierce hole, louvers can become a fastener or they can be used to locate parts for assembly. Half shears are used to create shear buttons and sheet locators for spot welding or assembly by piercing and forming a round shape halfway through the material so they protrude from the sheet. However, a rooftop half shear can also be used to create a solid, secure way of fastening parts together. Extrusions are usually used for tapped holes or pass-through holes for wire or tubing. They are typically round holes with the edge formed up to create a flange that can also be used in connecting applications.

For applications requiring less common punch forms, a variety of innovative joining tools have been developed to deliver significantly faster fastening of sheet metal components. Incorporating these connective forms into existing fabrication processes can simplify and speed up the assembly process while eliminating secondary operations. While often used for applications such as creating airflow vents, decorative forms, location markers, shear tabs and wire harnesses, lance and form tools are also ideal for producing clip attachments. Lance and form tools cut the material in the punch press and form it for use in fastening applications. Thread forms provide a fast, cost-effective way to hold sheet metal finishing screws in place. In particular, they help eliminate secondary operations where a threaded hole is needed in thin material. Using a thread form tool, a helical spiral is created that accepts the thread pitch of a given sheet metal screw. The screw holds firmly due to the metal tension in the thread form. Unlike lock nuts and other threading methods, there are no extra parts or additional assembly time required.

Applications with a maximum thickness of 2/3 x pitch-inch require a round pre-punch (keyhole if stainless or pitch is less than 0.050 in [1.3 mm]). The screw type, style and pitch should all be identified prior to fabrication. Coining may be required for applications with a material thickness that exceeds 2X (2/3 x inch-pitch), but may not work in all cases. Need to secure nuts and bolts in your material? Consider using a triple lock tool to create a form right in the part to hold these fasteners in place. Adding hinges to part assemblies is an extremely common forming application that can be labor and resource intensive. A variety of innovative hinge tools make it possible to fabricate fully integrated hinges and eliminate the need for costly hardware and a second operation to weld or fasten them. Producing a fully enclosed hinge requires two tools and three hits: Using a progressive forming tool, the first and second strokes wipe up the knuckle, then, using a rollover tool the third stroke curls the form over to create the hinge. Depending on the required length of the hinge, performing three forming strokes per knuckle can be time consuming.

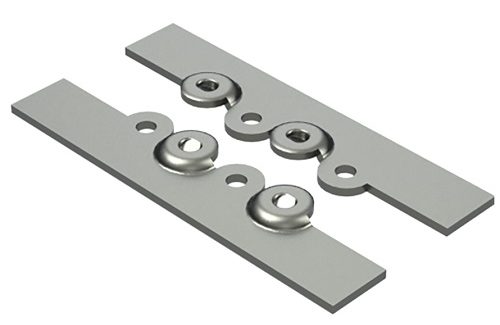

Incorporating a cam-style die assembly (such as Opti-Bend) when producing wider hinge knuckles, hinges with pins larger than .250 in, or hinges made of thicker material, can wipe up the knuckle in a single stroke and save valuable time. When the application allows, producing an open style or half-knuckle hinge using a one-hit hinge tool can improve efficiency by up to 900 percent compared to traditional hinges. One-hit hinge tools create multiple half-knuckles in a single stroke that function as hinges. Because this type of tool does not wipe up the material, one-hit hinge tools can be used for hinges requiring larger diameter pins. Finally, lance and form tools (such as Zip-Tech tooling) fabricate snaps that can be used to join metal parts together without welding or other fastening methods. The snaps formed using this method allow parts to connect so tightly, they virtually cannot be pulled apart.

Incorporating connective forms into your existing fabrication assembly process will add functionality to sheet metal components in the place of conventional fastening methods. So whether you choose to use a common punch forming tool you already have on the shelf or one of the joining tools described above, producing strong, lasting connections can be done quickly and easily in the punch press. Available for most styles of punch press, connective forming tools remove secondary welding, fasting and clipping operations to reduce assembly time and produce valuable cost savings.