Fabricating and Repairing 4130 and 4140 Steels in Heavy Equipment Welding

The strength of these steels is great for parts that require high strength and durability, but their higher carbon, chromium and molybdenum levels also make them more susceptible to cracking. Here are some insights into welding these steels during new fabrication and in repair, and how the right filler metal can help ensure success.

Posted: September 22, 2018

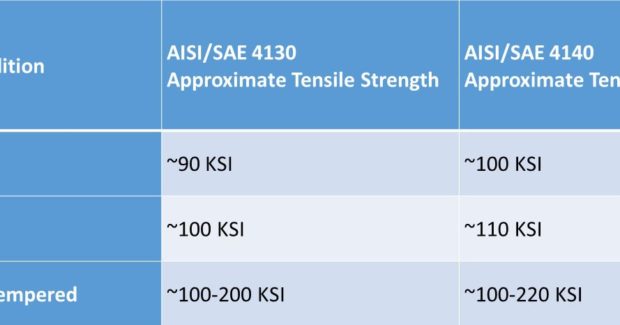

The fabrication and repair of shafts, gears, forgings and many other heavy equipment applications call for materials that can withstand tough, demanding conditions. In these cases, AISI/SAE 4130 and 4140 low-alloy steels are often used because their chemical composition allows them to be heat treated to high tensile strength and hardness. AISI/SAE 4130 and 4140 specifications refer to a chemical composition range only, as opposed to both a chemical composition and mechanical property ranges. Both 4130 and 4140 have carbon, chromium (0.80 percent to 1.15 percent) and molybdenum (0.15 percent to 0.25 percent) as primary alloying elements. They differ slightly in their carbon content: 4130 has a nominal 0.3 percent carbon, while 4140 has a nominal 0.4 percent. The strength of both materials can change greatly depending on the thermal treatment that has been performed: annealing, normalizing or quenching and tempering. Flame hardening can be used to additionally harden the outside of these materials while keeping the interior relatively soft.

Their strength makes 4130 and 4140 steels well-suited for components such as gears that require high strength and durability. However, the higher carbon, chromium and molybdenum levels that make these materials strong and highly hardenable also make them more susceptible to cracking. Consider the common challenges and best practices for welding 4130 and 4140 steels, both in new fabrication and in repair welding, and how the right filler metal can help ensure success.

TIPS FOR WELDING 4130 AND 4140 STEEL

Many of the challenges and best practices for welding 4130 and 4140 steels are the same whether the application involves welding new material or making repairs. Consider these six important steps when welding or repairing 4130 and 4140:

- Identify thermal treatment. New fabrication is typically performed on material in the annealed or normalized condition. It’s not recommended to weld 4130 or 4140 steel in the quench and tempered or case-hardened conditions without first performing annealing or normalizing in the area to be welded.

- Select a filler metal. Choosing the proper filler metal for 4130 and 4140 steels depends on the condition of the material before welding, the component design requirements and the desired condition of the material following welding. For material left in the as-welded or post-weld stress-relieved conditions, matching the tensile strength of the base metal as-supplied is a common determining factor during filler metal selection. It is typical to use a low-alloy filler metal that does not share the chemical composition of the 4130/4140 base material, but one that still provides suitable mechanical properties for both the as-welded and post-weld heat treated (PWHT) conditions. However, if a component is to be repaired numerous times in its lifespan – with each repair demanding a post-weld stress-relief cycle – ensure that the filler metal will continue to provide desired mechanical properties after the total stress-relief time.

Under-matching the tensile strength of the 4130 and 4140 base metal – choosing a filler metal that is weaker than the base metal – allows improvement of weld metal ductility and fatigue life, but may not allow the weld to resist high stresses required by a particular component’s design. Overmatching tensile strength of 4130 and 4140 weldments – choosing a filler metal that is stronger than the base metal – is typically not recommended, as the additional tensile strength correlates with a loss of ductility that can further increase the crack susceptibility of the weld metal. Welds that are to be annealed or normalized after welding can benefit from a 4130 or 4140 filler metal, respectively. Although 4130 and 4140 filler metals produce a brittle as-welded deposit, the “reset” microstructure afforded by annealing or normalizing restores the ductility of both the weld metal and heat-affected base metal.

Welds that are to be quench and tempered after welding require the use of a 4130 or 4140 filler metal, as most low-alloy filler metals of sufficient tensile strength lack the carbon required to respond appropriately following a quench and temper option. - Apply preheat. The higher hardenability of 4130 and 4140 steels increases the ease at which a hard, brittle microstructure in the heat-affected zone or diluted weld metal is formed following welding. Preheating is necessary to achieve consistent, high-quality welds. Establishing and maintaining a minimum preheat and interpass temperature slows the cooling rate of the weld and base metal to prevent or minimize the formation of brittle microstructures. Ensure proper preheating by using sufficient temperatures, typically from 550 deg F to 800 deg F when welding thick components, and heating through the entire thickness of the base material, rather than only achieving temperature on the surface. Using induction heating can help efficiently achieve proper heating throughout the part. Also, be sure to establish the preheat temperature a sufficient distance from the weld joint, typically a minimum of three inches in all directions. Larger weldments may benefit from an even greater preheat area around the weld joint.

- Perform welding. Similar to preheat and interpass temperature, when heat input is too low it can accelerate the weld cooling rate to a point where brittle microstructures form, which harms ductility and toughness. Heat input is increased by increasing voltage and amperage, and reducing travel speed. Consider the effects of these variables when developing a welding procedure for joining 4130 and 4140 steels.

- Slow cooling. Holding the weldment at the preheat temperature for some time after welding, followed by covering the weldment in ceramic insulation, is beneficial because this allows the diffusion of hydrogen from the weld metal and the heat-affected zone (HAZ). A holding time of 30 minutes to an hour per one inch of base material thickness is recommended. This process is informally known as hydrogen bake-out, and it is different from post-weld stress relief.

- Apply post-weld thermal treatment. Post-weld heat treatment can help relieve stresses created by welding that can contribute to cracking in the finished weld. The release of these residual stresses may also be beneficial prior to machining to help maintain tight tolerances. Thin material (less than 1/8 in thick) typically does not require stress relief because cracking is less of a concern. Thicker materials are commonly stress-relieved at 1,050 deg F to 1,250 deg F for approximately one hour per inch of base material thickness. As mentioned before, always consider the times and temperature of a post-weld thermal treatment — whether PWHT, annealing, normalizing, or quench and tempering — to ensure that the filler metal to be used will provide or maintain adequate mechanical properties.

TIPS FOR REPAIRING 4130 AND 4140 STEEL

Repairing 4130 or 4140 steel is often more complicated than new fabrication with the materials since the component being repaired can be worn, greasy or dirty. It also may be more difficult to gather information on the material’s prior thermal treatment. Always consult the original equipment information for guidance and to gain a better understanding of any thermal treatments or design requirements of the component. It’s especially critical to identify how the part was heat treated – if it is annealed, normalized, quenched and tempered, or flame hardened – before completing a repair. A part that has been quenched and tempered, for example, is typically less ductile and more crack sensitive, making it much more difficult to repair. In these cases, localized annealing or normalizing around the weld before repair can help, but be aware that this affects the material’s strength. A hardfacing product may be needed if surface hardness was a primary consideration. If restoring base material strength is necessary, it can be conditioned again using thermal treatment after the repair.

Properly preparing the material before repair also helps ensure high weld quality. Welding over oil or grease can contribute to porosity in the weld metal and diffusible hydrogen in the weld deposit, increasing the potential for hydrogen-induced cracking. Simply removing visible oil and grease may not be sufficient. Instead, consider steam degreasing to remove contaminants trapped deep within the pores of the base material opened by elevated temperatures. Here are some additional tips for two specific types of repair:

- Crack repair: Regardless of base material, crack repair is complicated. Repairs often suffer from higher joint restraint that introduces additional stress and increases the risk of cracking. Before attempting repairs, perform dye-penetrant (PT) or magnetic particle (MT) inspection to identify the full extent of the crack. Remove the cracked area using grinding or an arc-gouging process. The removed area should form a wide “V” or “U” to help prevent lack of fusion or solidification cracking from occurring during welding. Use preheat when performing any arc-gouging process for the same reasons that preheat is used during welding. To minimize the risk of an existing crack continuing to propagate during a repair, drill both ends of the crack. Before welding, ensure that the crack has been completely removed, again with either PT or MT. After this extensive preparation, welding can finally begin.

- Build-up and overlay: This type of repair refers to restoring components to their original dimensions and, in the case of overlay, applying a deposit that provides hardness comparable to what may be achieved from quenching and tempering or case hardening. To successfully complete these repairs, consider build-up and overlay filler metals. Overlay products tend to be harder than build-up products, but often have thickness limitations, while build-up products typically do not. This means when using overlay products beyond a certain number of layers, the weld deposit doesn’t have good ductility and may be crack sensitive or simply splinter from the base metal. Build-up products are used to restore a product to dimension when the thickness to be restored exceeds that allowed for an overlay product.

CLOSING THOUGHTS

Because of the high hardenability of 4130 and 4140 steels, filler metal selection, hydrogen control and cooling rate are critical considerations to obtain the best results. To help ensure success in heavy equipment welding applications:

- Verify all design requirements and base material thermal treatment before welding.

- Choose a filler metal that provides sufficient mechanical properties for parts left in the as-welded or stress-relieved conditions.

- Choose a filler metal that matches the chemistry of the base metal for components to be annealed, normalized, or quench and tempered after welding.

- Select a minimum heat input and preheat/interpass temperature to help slow the weld cooling rate.