Getting Down to Business: Walter Surface Technologies

An entrepreneurial spirit and vision fuels the innovative drive behind the aggressive growth strategy of this manufacturer of surface treatment technologies.

Posted: September 4, 2018

“We began hard, but we’ve grown soft,” was how Walter J. Somers fondly described the way business at Walter Surface Technologies (Pointe-Claire, QC), the company he founded in 1952, had grown over time: The original J. Walter Company began by manufacturing vertical grinders, jigsaw power tools, angle grinders, cold saws and assorted hardware used for grinding and cutting steel and similar hard metals. But over the years, Walter Surface Technologies grew by expanding into the science and engineering of abrasives, chemical solutions and applied surface treatment technology used in grinding, drilling, cutting, welding, rust removal, polishing and finishing a wide array of metals, including stainless steel and aluminum. “Everywhere there’s metal, we are there,” is the motto of Pierre Somers, the founder’s son who is now the chairman and chief executive officer of the company. Under his leadership, business has expanded globally into nine countries across the Americas and Europe by penetrating fabrication sectors in mining, oil and gas, construction, automotive, transportation, aerospace, food preparation and pharmaceutical markets.

The entrepreneurial spirit and vision of the Somers family has been adopted by company president and chief operating officer Marc-André Aubé, who oversees an aggressive business strategy directed toward continuing global expansion, and by vice president of research and development Patrick Lapointe, who manages their product lines, engineering, technical support, intellectual properties, patents and trademarks from the 92,000 sq ft international campus of their world headquarters in Pointe-Claire. Fabricating & Metalworking recently toured this $30 million complex, which includes laboratories, test centers, marketing, sales, warehousing, distribution, after-sales service, and a high-tech Bio-Circle bottling plant that increased production of their VOC-free cleaning solutions by tenfold. The visit was highlighted with technical presentations and live demonstrations by Lapointe and his team that displayed how some of their latest innovations are being used by customers to become more competitive through:

- Reducing consumables, labor and overall operating costs.

- Addressing the skilled labor shortage.

- Efficient processing of stainless steel and aluminum.

- Improving environmental sustainability.

REDUCING COSTS THROUGH INCREASED PRODUCTIVITY

Lapointe started with the economical Flexsteel™ general purpose flap disc that is ideal for use on steel in light industrial, metal fabrication and construction applications. It offers a high removal rate and good life when blending sharp corners, heavy deburring or blending in fillet welds. “We have seen our biggest growth in this flap disc, which has a mid-market price point in an underserved market,” noted Lapointe. “It features a specially-engineered zirconia alumina abrasive grain blend that self-sharpens with less pressure, allowing it to maintain a high removal rate on any power tool, including those with less torque.” Flexsteel withstands lateral pressure to remove material from corners and edges that would normally cause premature wear on the standard abrasive cloth typically found on flap discs in this category, and its unique Eco-Trim backing extends disc life.

As fabricators shifted towards lightweight magnetic drills for heavy duty operations, Walter redesigned their powerful ICECUT™ 100 and ICECUT 200 portable magnetic drills that can safely drill large holes, regardless of user experience, to lower production and labor costs on any jobsite. “These units weigh 22 lb and 27 lb, respectively, and use ACCUDRILL™ pressure guide technology that protects against motor overload and overheating and reduces the risk of cutter breakage,” said Ryan Boyd, the product manager of tooling and power tools. “Their ergonomic control panel centralizes controls for efficient drilling on either side of the unit. A mandrel support absorbs vibrations for stability and perfect centering so that the motor and chuck are perfectly aligned for precise cutting with little chance of cutter damage.” A lightweight, ergonomic and smooth-grip handle makes unit positioning and drilling operations easy, while a separate quick-release and reversible handle enables easy positioning in confined spaces.

That’s not all. “Integrated wiring eliminates obstructions when drilling or repositioning the unit. No wires mean no mishandling failures – that’s convenience,” added Boyd. “A steel sliding guard keeps operators safe for worry-free drilling, free of errant chips and lubricant splash. Maintenance is easy: direct access to the unit’s carbon brushes makes tune-ups simple and keeps the motor operating at maximum power. For higher mobility, the one-speed, 850 watt motor on the ICECUT 100 delivers 600 rpm at 8.5 amps. When versatility and power is a must, the ICECUT 200 has a two-speed 1,200 watt motor for 300-600 rpm at 12 amps that is ideal for a wide range of jobsite work.”

STAINLESS STEEL AND ALUMINUM APPLICATIONS

For the growing number of shops that compete in stainless steel fabrication, the Zip Stainless™ thin cut-off wheel is free of iron, sulfur and chlorine, and guaranteed not to contaminate stainless steel or other nickel alloyed steels. “That saves time and reduces operational and labor costs,” explained Marc Brunet-Gagné, the product manager of bonded abrasives. “A new bond matrix significantly improves the life of this cutting disc, providing up to 40 percent more cuts – cool, free cuts – and the best overall performance on stainless steel and nickel-alloyed steel. Its Type 27 design allows more clearance for flush cutting and the metal hub cladding delivers extra strength, control, and safety when operators need it most.” The Zip Stainless comes in exclusive protective packaging that preserves these physical properties until ready for use.

Stainless steel and aluminum fabricators are drifting away from traditional wire brushes and harsh chemical cleaning solutions that are too costly and sometimes toxic to more efficient, environment-friendly electrochemical weld cleaning systems. “Wire brushes clean welds fast, but they scratch soft alloys like aluminum and alter their finish,” stated Lapointe. “Strong chemicals can clean welds but, depending on their type, they can also cause surface damage, health hazards and expensive disposal issues. Our Surfox 305 electrochemical weld cleaning system uses a safe and pH-neutral solution that won’t damage stainless steel or aluminum, giving users more bang for their cleaning buck.” Surfox 305 can rapidly clean a MIG, TIG and spot welds at 3-5 fpm by using a pH-neutral electrolyte solution that is pumped directly to the surface being cleaned. A dynamic electrical current control prevents micro-pitting on weld surfaces.

Compared with toxic pickling pastes that require an hour or more of application before removal, the advantages of non-toxic electrochemical cleaning become obvious. “Pickling of stainless steels involves strong acidic solutions of nitric and hydrofluoric acids that are applied as paste and take an hour to work before being rinsed off the metal,” explained Lapointe. “Costly environmental compliance measures may require special wastewater disposal techniques for toxic acids that can cost up to $8 per liter for disposal of pickling paste and associated liquids. But with Surfox 305, once a weld is cleaned the residue is simply wiped off. The electrolyte solution is phosphorus-based and not considered a dangerous liquid, so there’s no added cost for disposal. Moving to an electrochemical cleaning solution can also optimize welding processes.” After the initial investment in the machine, brushes are about $50 each and last 8-10 hours. The liquid is inexpensive, running about $3 per day for a busy shop.

SUPERIOR MIRROR FINISHES

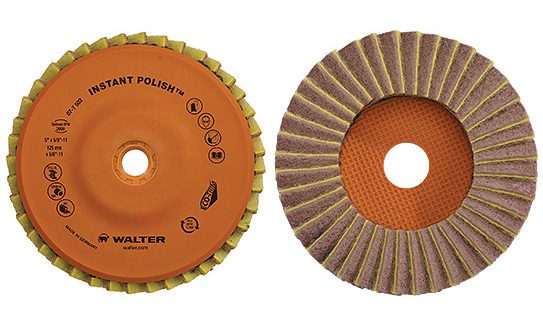

For polishing and finishing projects, fabricators can attain exceptional polishing results in a single, fast and easy step with new Instant Polish™ flap discs that boast powerful polishing properties and superior engineering to easily achieve No. 8 mirror finishes in a single step – saving them more time and money. This latest innovation lowers metal roughness averages (Ra) by 20 µin and achieve mirror finishes at Ra ratings less than 4 µin on tough polishing jobs. “The science, research and product development behind these flap discs is second to none,” noted Jonathan Douville, the senior product manager of Surfox, finishing and coated abrasives. “Instant Polish flap discs are available in 4½ in and 5 in diameter sizes for use at a maximum 7,300 rpm and optimal 2,000 rpm in automotive, transportation, food and beverage equipment, aerospace, naval and pharma industries, and other sector-specific applications.”

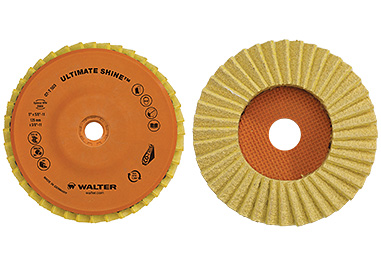

When ultra-high performance finishing capability is a priority, Ultimate Shine™ flap discs are a second step towards achieving a consistent surface finish and exceptional mirror finish time and again, with Ra ratings under one micro-inch. Long-lasting and versatile, these flap discs are the ultimate tool for consistent capabilities on a wide range of finishing projects. “The Ultimate Shine flap disc is a high performance, long-lasting and productivity-enhancing finishing tool that helps our customers work better,” said Douville. “These flap discs are also available in 4½ in and 5 in diameter sizes for use at a maximum 7,300 rpm and optimal 2,000 rpm on stainless steel, steel and non-ferrous metals when used with angle grinders.”

Walter Surface Technologies, 5977 Trans Canada Highway, Pointe-Claire, QC H9R 1C1, 514-630-2800, www.walter.com.