Industrial IoT Application for OEMs and Equipment Distributors

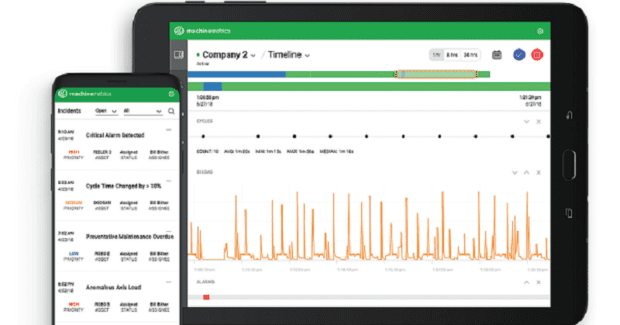

Using AI and predictive maintenance that is designed specifically for the user’s equipment, MachineMetrics Service from MachineMetrics remotely monitors machine assets in the field and at customer sites in real-time to improve equipment uptime and reduce service costs.

Posted: September 27, 2018

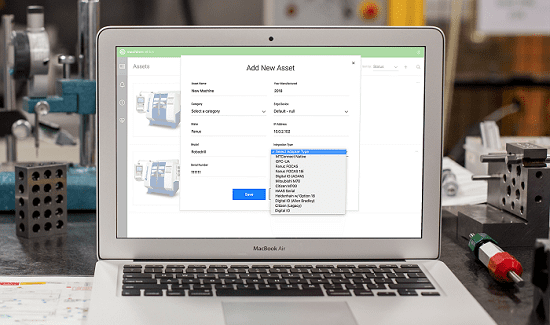

What if you could diagnose and resolve problems for your customers without ever leaving your office? When customers require after-sales service, they expect their problem to be solved with minimum delay. Too many service calls require expensive and time consuming on-site visits. This means equipment providers require remote access to monitor and assist with user operations to troubleshoot problems, resolve service events and monitor preventative maintenance tasks, all without leaving their office. In Booth A-2513, MachineMetrics Service from MachineMetrics (Northampton, MA) is an Industrial IoT application that remotely monitors machine assets in the field and at customer sites in real-time. By providing AI and predictive maintenance that is designed specifically for the user’s equipment, they can improve equipment uptime and reduce service costs. Industrial IoT for equipment providers:

- Allows remote monitoring and improved service for all user machines in the field.

- Enables their service team to diagnose and resolve equipment problems in real time.

- Track Utilization of equipment over time to understand current and potential capacity.

- Work with customers to predict equipment failures and prescribe solutions before they occur.

- No need to install on customer’s internal IT infrastructure with included cellular support.

MachineMetrics Service provides service teams a chance to diagnose and resolve machine problems without the necessity of an on-site visit, gain insight into customers’ equipment health and condition with historical machine data, identify new service opportunities with analytics and reporting, predict and deliver early warning of potential equipment failures and highlight elevated risk areas that lead to machine downtime, and determine and take preventative action before it impacts a customer’s machine performance. Through the powerful benefits of remote monitoring, service teams can focus on addressing issues that may immediately impact the customer while MachineMetrics Service keeps an eye on big-picture issues that benefit everyone:

- Empower your service team by eliminating the necessity for on-site machine service and maintenance.

- Detect new service opportunities and diagnose asset performance issues remotely.

- Understand equipment utilization rates and overall install base health.

- Capture and scale technical service expertise of workforce.

- Gain insight into asset and service model through visibility of pervasive issues.

- Improve equipment uptime and field service productivity.

- Reduce unscheduled downtime with real-time machine condition alerts.

MachineMetrics, 5 Strong Avenue, Suite 201, Northampton, MA 01060-3916, 413-341-5747, www.machinemetrics.com.