Innovative Press Brake Tools Eliminate Secondary Operations, Lower Costs

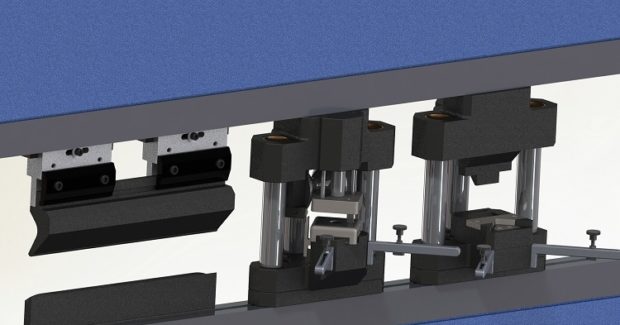

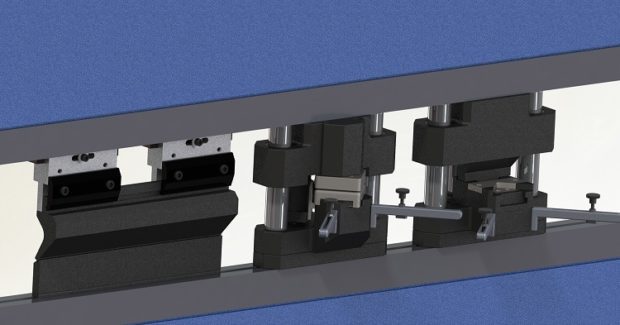

The corner forming tool from Wilson Tool eliminates secondary operations by bending and finishing corners in the press brake, and their new Brake Partner holder mounts existing punch press tooling in a press brake to produce holes and forms in-house.

Posted: September 27, 2018

In Booths A-2221 and B-6251, Wilson Tool International (White Bear Lake, MN) will feature a variety of innovations to help fabricators increase efficiency by eliminating secondary operations and improving tool handling. Typically, fabricating a four-sided sheet metal pan is a time consuming process that requires multiple bends on the press brake, followed by secondary welding and grinding operations to finish the corners. The new Corner Former corner forming tool makes it possible to bend and finish corners in the press brake. It saves time by eliminating secondary operations and produces a higher quality part with a smoother finish. As fabricators have migrated from punch presses to laser cutting machines, fewer punch presses are available in shops for punching and forming operations.

Wilson Tool International, 12912 Farnham Avenue, White Bear Lake, MN 55110, 866-752-6531, www.wilsontool.com.