Quicker, Easier Handling of Large, Detailed 3D Inspection Data

Artec Studio 13 software from Artec 3D uses new high-powered algorithms that allow users to produce, edit and process 3D data with ease, no matter an object’s size nor resolution.

Posted: September 26, 2018

Artec 3D (Santa Clara, CA) has unveiled their high-tech and streamlined Artec Studio 13 software with new high-powered algorithms that allow users to produce, edit and process 3D data with ease, no matter an object’s size nor resolution. Even a 500 million polygon data-set is no challenge for this software. Global registration, a tool needed for the creation of every model, can successfully assemble up to 250 percent more object types, even when scanning conditions are subpar. In addition, the tool is now up to double the speed and fine registration is up to 50 times faster so that users can quickly jump to the next stage in data processing.

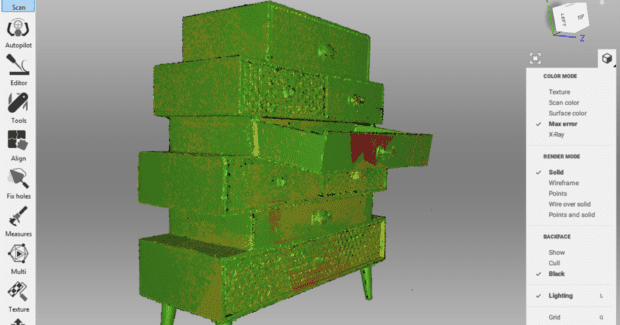

This latest software release also incorporates a new X-ray Mode, a first-of-its-kind feature that provides users the ability to examine raw scan data for potential problem areas, prior to entering the processing stage. The new X-ray Mode makes raw scan data semi-transparent and deletes all the noise around a scanned object, showing users the data that they want to see. As a result, it’s much easier to judge the quality of scan data right after capture, without the need to process it first. Users can immediately identify if areas of an object were missed, or if there were holes, misalignments or other issues that occurred during the scanning process. This makes scanning even the most complex objects a simple task.

“The fact that Artec Studio is now able to flawlessly handle data sets that allow an individual to capture and process large objects without limitation and in high resolution is incredible,” said Artyom Yukhin, the president and chief executive officer of Artec 3D. “From X-Ray Mode to new algorithms to an advanced Global Registration tool, all these new features that are now available make working with scans of a large or highly detailed object much more streamlined and less time-intensive, no matter a user’s skill level. It’s the perfect complement to unleash the potential of our full line of 3D scanners.”

In Artec Studio 11 the Autopilot tool was introduced, a fully automated mode for processing 3D data. In Artec Studio 13, users are presented with 3D Radar that makes the scanning process from beginning-to-end much more intuitive. 3D Radar projects a distance map onto your data capture and guides you to hold the scanner at the optimal distance for capturing the most accurate geometry and vivid colors of your object. During the scanning process, data is displayed in shades of red, green or blue to indicate the scanner is too close, just right or too far away, respectively. This feature even works with older versions of Artec scanners and makes 3D scanning any object significantly simpler for both beginners and expert users. To further ensure the highest quality model, the Max Error Mode has been upgraded to automatically inspect and highlight any areas that may need extra attention, creating a faster workflow.

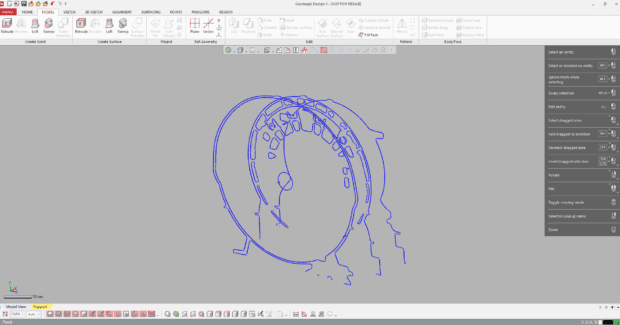

Artec Studio 13 includes smart 3D rendering to automatically detect the user’s computer specs. If the user’s computer lacks in power, smart 3D rendering will adjust accordingly to use less RAM, yet still provide the smoothest possible user experience when working with large volumes of data. Additionally, users can easily make DXF sections of any 3D model and can export even open contours to CAD software such as Design X or SOLIDWORKS. Artec Studio 13 supports Artec’s full suite of long-range and handheld 3D scanners, including the latest Artec Ray and Artec Leo.

Artec 3D USA, 2880 Lakeside Drive, #135, Santa Clara, CA 95054, 669-292‒5611, www.artec3d.com.