Servo Presses Increase Productivity, Improve Part Quality in Near-Fine Blanking and HSLA Blanking

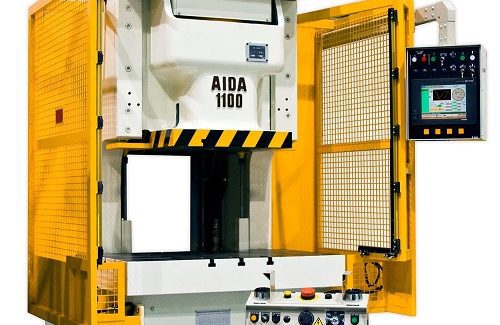

The DSF-C1-1100 110 ton gap frame servo press and DSF-N2-3000 300 ton two-point straightside servo press from AIDA-America provide more flexibility to the press room than traditional fine blanking presses and a much more efficient, economical stamping process.

Posted: September 25, 2018

In Booth A-2009, AIDA-America Corporation (Dayton, OH) will demonstrate two DSF Series direct drive servo presses, powered-up and blanking parts: First, a DSF-C1-1100 110 ton gap frame servo press will blank HSLA parts with an optimized servo silent blanking stroke motion profile that can only be achieved on a servo press. This demonstration will highlight the versatility of these servo presses and show how they can improve virtually any stamping operation with increased productivity, improved part quality, extended die life, reduced maintenance and more. Next, a DSF-N2-3000 300 ton two-point straightside servo press will be part of a full progressive die production line blanking near-fine parts to demonstrate how servo near-fine blanking can produce an over 90 percent burnished surface with a straight edge, exceeding the typical 70 percent to 80 percent burnished edge requirement of many applications.

The combination of DSF Series servo press accuracy and programmability is utilized to transition near-fine parts from a high cost, labor intensive machine process to a much more efficient, economical stamping process, presenting the opportunity to dramatically reduce the per piece cost. DSF Series servo presses also provide more flexibility to the press room than traditional fine blanking presses. This production line is made possible through the cooperation of Portland Products, Inc. (Portland, MI), who will be taking delivery of the press after the show. AIDA-America will also be coordinating with Dallas Industries (Troy, MI) and Pax Products Inc. (Celina, OH) for this demonstration and will be exhibiting their exclusive Allen-Bradley-based servo press control, the latest in servo press control technology for servo presses from 315 tons to 3,500 tons. The fully operational and interactive Allen-Bradley control will demonstrate several servo press stroke motion profiles in real-time on a virtual press.

AIDA-America associates will be available to discuss examples of production optimization driven by DSF Series servo presses used in stamping operations. They will share how these infinitely programmable presses can help maximize stamping productivity and profit in the pressroom.

AIDA-America Corporation, 7660 Center Point 70 Boulevard, Dayton, OH 45424, 937-237-2382, info@aida-america.com, www.aida-global.com.