Acquiring Complex Machined Parts in the “No Bid Zone”

Pharmaceutical equipment builders demand machined components with such ultra-high tolerances and complexity that many precision shops must pass on jobs that are simply too difficult or beyond their capability. Who can they turn to?

Posted: October 25, 2018

To safely produce reliable, life-saving drugs with consistent dosing, pharmaceutical equipment manufacturers build systems that are constructed of machined components designed to meet tough demands for exceptionally high tolerance and complexity. The difficulty here is that many machine shops, even high precision operations, typically machine parts down to .001 in tolerance. When ultra-high tolerances down to .0001 in are required, a significant number of these shops suddenly enter the “no bid zone,” where contract part manufacturers pass on jobs that are simply too difficult or beyond their capability.

“Many shops will not bid on an ultra-high tolerance part because they are concerned about the amount of time and effort it will take to meet the required tolerances,” says a seasoned engineering manager at a pharma equipment builder that designs and builds their own systems for filling and packaging. “In this industry, a part that is 99 percent ‘right’ may not be good enough. For one job, we sent some ultra-high tolerance work to a shop that machined about 30 parts, but we had to reject them because they failed independent third-party measurement and functional testing.” Fortunately for pharma equipment manufacturers that need help with complex components in the “no bid zone,” there are other suppliers capable of consistently producing ultra-high tolerance parts who all share something in common: for them, it is usually not a matter of having superior CNC equipment, but rather a combination of experience in the unique challenges in machining and inspection that are required to hit the mark every time.

OVERCOMING PRECISION MACHINING CHALLENGES

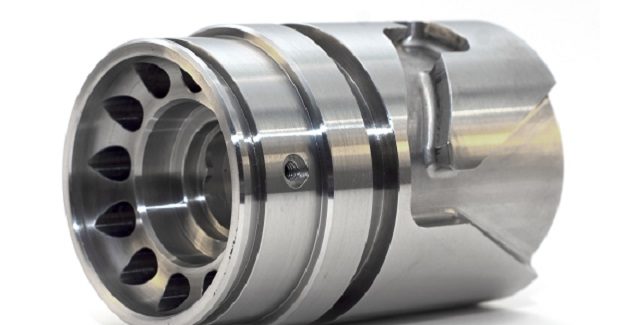

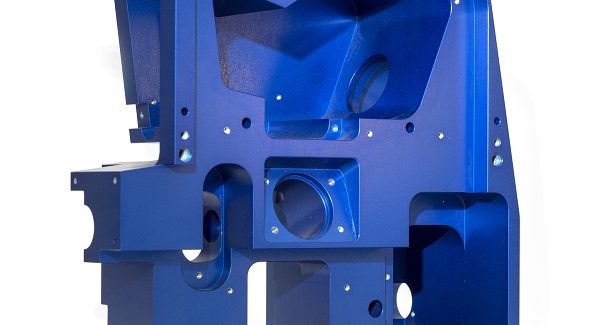

Pharmaceutical production equipment that is used to handle, mix, process and package medications in precise quantities demands that the CNC machining of its components be excruciatingly precise. This includes parts with tolerances down to .0005 in and less, machined out of 316 stainless or exotic metals such as titanium, Invar, Kovar, and Nitronic 60. An increasing number of builders want high tolerance parts made out of ceramics and PEEK plastics. To avoid the substantial downside of dealing with failed parts, pharmaceutical engineers send higher tolerance work to contract shops with a proven background in machining such components. One example is Silicon Valley Manufacturing (SVM; Newark, CA), which has specialized in high volume, “lights out” precision CNC milling and turning services and 5-axis prototype manufacturing since 1997. Pharma equipment builders typically seek them out because they consistently hold ultra-high tolerances down to ±0.0001.

“We go to SVM because they will machine really difficult parts that many other shops turn down and don’t even bid,” states the engineering manager. “This includes both round and tapered parts with tolerances in the range of .0001 in to .0002 in. It can be tough to match such high tolerances in every way because in every component there could be 100 dimensions that must all be near perfect. SVM is able to make highly precise parts that match the print.” Achieving extremely high tolerances requires paying attention to minute details and factors that go well beyond the demands of typical “precision” parts. SVM owner Mark Serpa, explains how this is really an employee mindset that begins inside the operating philosophy of “no part is too complex to figure out.”

“We can hire extremely experienced people or train employees, but if they do not have the right mindset, no years of experience helps because these type of parts cannot be machined like ‘all other parts,’” notes Serpa. “This requires a team of different personalities, education, experience and age levels all working together. That makes a huge difference.” To ensure that ultra-precise tolerances are achieved on every part, state-of-the-art quality control systems must also be in place. At SVM, their measuring equipment includes a Zeiss Contura G2 with scanning coordinate measuring machine (CMM) capability for inspection down to 0.00005 in, a MicroVu Vision System with 575X magnification and a Starrett 14 in digital comparator with 50X magnification. Serpa says ultra-high levels of precision may even dictate that the same style and brand of inspection equipment be used on both ends: “To enhance reliability and ensure an ‘apples to apples’ comparison, we have even had to purchase inspection equipment that matches what our customer uses in their facility.”

Even the way each part is handled and moved from point to point can affect how accurately it is measured. “You must think about positioning: where the part sits and how it is handled,” explains Serpa. “You must consider how it moves from machine to machine, from person to person, because all of these factors can affect measurement when tolerances are that extreme.” In some cases, a short period of time may be required so that parts can acclimatize to a new environment. “Different types of materials expand or contract with temperature at different rates. This must be accounted for when extreme tolerances are required,” says Serpa. “You cannot simply grab a part off a shipping shelf and test it or you may get a different result.” When ultra-high tolerances are involved, the role of quality control personnel must also shift from simply assessing pass/fail of parts to engineering support. “QC inspectors not only tell the machinist if the part is to print or not, they must also work with them to solve machining issues that are contributing to the parts not passing,” adds Serpa. “This is not the standard mentality in our industry. It requires a different skillset, level of work and responsibility.”

PHARMACEUTICAL HYGIENE

Since the pharmaceutical industry must maintain safety at all stages of manufacturing, the hygiene and cleanliness of production equipment components is a top priority. In another job at SVM, the ability to easily disassemble and clean equipment was a major consideration. Part count reduction and tool-free assembly were high-priority design goals that led to fewer – but more complicated – parts. Many of these parts required very high tolerances because they were used in precision mechanisms. Others needed high precision to fit together well and ensure that the custom filling equipment would not allow any product to leak. The parts were generally made of 316L or 17-4 (Type 630) stainless, along with a few made of PEEK or Acetron GP. High precision plastic and steel parts were used together to allow trouble-free motion guidance in an environment where lubrication is not permissible.

For such a demanding application, Serpa suggests it is critical that the customer understands the value added in engaging in an ongoing collaboration with their vendor. “As a result of the collaborative process, we are able to discover together how to make extremely complex parts more accurately and reliably,” he says.

Silicon Valley Manufacturing, 6520 Central Avenue, Newark, CA 94560, 510-791-9450, sales@svmfg.com, www.svmfg.com.