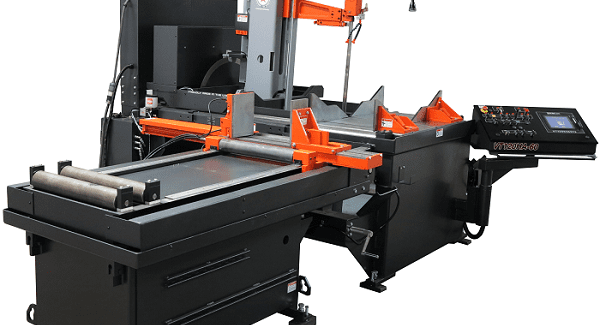

Automatic Vertical Band Saw Makes Straight and Miter Angle Cuts on Structural Shapes

The list of materials ranging from structural steels to high tensile specialty alloys shown on the touch screen of the VT120HA-60-CTS vertical band saw from HE&M Saw displays the recommended blade speed, cutting rates and blade pitch for each type and size of material.

Posted: October 2, 2018

In Booth B-6243, the VT120HA-60-CTS automatic and programmable vertical band saw from HE&M Saw (Pryor, OK) is ideal for cutting a wide variety of materials, including structural shapes that require straight and miter angle cuts. This saw uses a 1-1/4 in x 16 ft 6 in x .042 in blade with a 4 deg blade cant, powered by a 5 hp motor. It has a cutting capacity of 18 in horizontal by 24 in vertical at 90 deg, 18 in by 16 in at 45 deg left miter, 18 in by 14.75 in at 45 deg right miter, 18 in by 10 in at 60 deg left miter, and 18 in by 9 in at 60 deg right miter. The VT120HA-60-CTS has touch screen controls that make programming and running jobs in automatic easy. Previous jobs can be saved and reloaded any time. A standard material list is available on the touch screen with a database of the most common materials, ranging from structural steels to high tensile specialty alloys, with each displaying the recommended blade speed, cutting rates and blade pitch for the type and size of the material.

A series of cuts to be cut from the same bar stock can be programmed with the touch screen by entering jobs that will be run in a sequence. A control panel and help files are also available from the touch screen to help assist in operating the saw and troubleshooting. The VT120HA-60-CTS on display will feature the new 48 in Ball-Screw Bar-Feed that is a smoother running servo-driven bar-feed with faster cycle times and more accurate positioning of material that allows for improved efficiency and more accurate part lengths. The bar-feed table incorporates rollers all the way through and is fully-panned. The feed vise on the bar-feed is bi-directional to provide clamping for mill bundles and to eliminate interference with metal straps or bands.

HEM Inc., PO Box 1148, Pryor, OK 74362-1148, 918-825-4821, www.hemsaw.com.