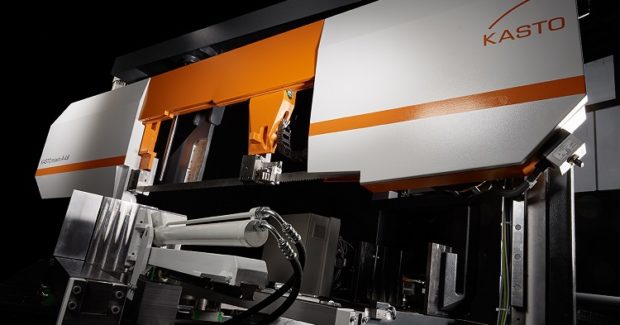

Double-Miter Bandsaw for Cut-To-Size Parts Used in Heavy Fabrication

For cut-to-size pieces in the steel industry, iron and steel trade, plant construction and special machine building, the KASTOmiwin double-miter bandsaw from KASTO makes cut-to-length and miter cuts between -45 deg and +60 deg.

Posted: October 5, 2018

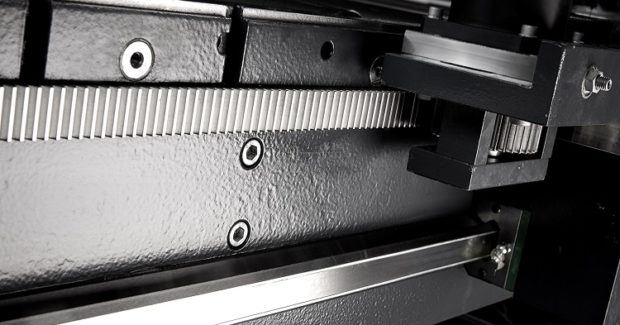

In Booth B-5829, KASTO Inc. (Export, PA) introduces the new KASTOmiwin double-miter bandsaw for cut-to-length and miter cuts between -45 deg and +60 deg. Initially available as the semiautomatic KASTOmiwin U 4.6 and the automatic A 4.6 version, it is designed particularly for cut-to-size pieces in the steel industry, the iron and steel trade, plant construction and special machine building. This new saw has an electrical saw feed drive with ball screw spindle. In the A-version, a rack-and-pinion drive provides the material feed. The single stroke of the material feed in the A-version is 3,000 mm with inaccuracies in cut lengths counteracted by skillfull placement of the vice to fix the material at right angles to the material flow direction in all cases, achieving miter and cut length accuracies in the ‘fine’ tolerance class.

The clamping range of the new bandsaw is up to 460 mm, depending on the material profile. The smallest size that can be cut is 10 mm x 10 mm. With single cuts, the KASTOmiwin leaves a remnant piece of 30 mm. In automatic mode, the remnant piece length increases to 200 mm for 90 deg cuts. The user can adjust the cutting speed steplessly from 12 m to 150 m per minute. The saw is designed to avoid wear resulting from sawing into the material support table. Nevertheless, cut pieces are available immediately behind the saw blade. The height of the material support bed is 700 mm. The space required by the new KASTOmiwin is 3,950 mm and 5,450 mm in the version with material feed. Positioning the saw head at an angle reduces the width to 2,980 mm – ideal for container transportation.

KASTO Inc., 3002 Venture Court, Export, PA 15632-8949, 724-325-5600, www.us.kasto.com.