Industry 4.0 Fiber Laser Cutting System

In line with Industry 4.0 real-time process, consumption and service monitoring, the Advanced 800 eX-F fiber laser cutting system from MC Machinery incorporates an all-new M800 control with enhanced industry-leading functionality.

Posted: October 6, 2018

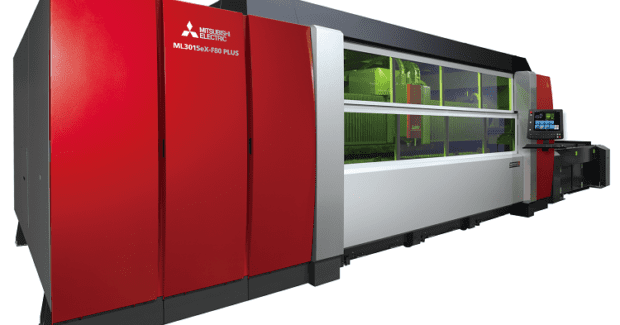

In Booth B-6329, MC Machinery Systems, Inc. (Elk Grove Village, IL) will display new laser processing systems, press brakes and live web demonstrations of their remote360 remote monitoring and support system. On display will be the Advanced 800 eX-F Series, the new flagship for their fiber laser line, incorporating an all-new M800 control with enhanced industry-leading functionality. In line with Industry 4.0, real-time process, consumption and service monitoring give the M800 control the most accurate data management to date. This provides users with the tools they need to improve green light efficacy and reduce service downtime. Processing speeds up to 100 m per minute are now possible, while also improving part accuracy and reducing processing time. This machine comes standard with Mitsubishi’s all-in-one Zoom Head that utilizes beam mode manipulation to process a full range of materials automatically without any setup.

Also on display will be the SR-F 4kW fiber laser with SmartFlex ELEMENT automation that delivers unsurpassed quality and speed at a great price point. Paired with the SmartFlex ELEMENT automation system, users can benefit from maximum versatility and throughput. Also on display will be the new BB and BH series press brakes with a next generation control that delivers an even friendlier user interface with greater ease of use, reduced set-up times and increased processing speeds. Control features include 22 in Windows-based monitor, 30 percent enhanced cycle times and a 3D graphical interface. Another highlight will be the new InspecVision 2D and 3D measurement system. The 2D system can be used to quickly measure or reverse engineering flat parts that have been manufactured on laser, plasma and waterjet cutting systems, as well as punched and some stamped parts.

MC Machinery Systems, Inc., 85 NW Point Boulevard, Elk Grove Village, IL 60007, 630-616-5920, www.mcmachinery.com.