Innovative Welding Accessories Reduce Cycle Times and Increase Production

The Gas Management System EWR 2, Fume Extraction Cyclone, ABIMIG AT air-cooled manual MIG torch and ABIROB Cyclone air-cooled robotic torch from Abicor Binzel all reduce operating costs and increase welding profitability.

Posted: October 10, 2018

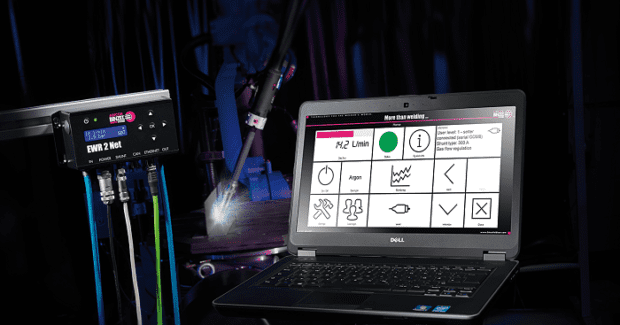

In Booth C-12328, Abicor Binzel USA, Inc. (Frederick, MD) will demonstrate their newly released Gas Management System EWR 2 that combines gas saving technology with network-compatible data acquisition. EWR 2 utilizes a closed loop monitoring system featuring fast-action solenoid valves to deliver gas with a software package that allows you to load your gas type, flow rate, and pressure. On average, this system saves 30 percent to 50 percent on shielding gas use and, with the software package, manufacturers are able to track their gas usage over a weld, a part, a production run, or any length of time desired. EWR 2 is also securable thanks to password-protected technology, so management can set their desired outputs while the production team monitors.

Also on display will be the new, single torch fume extraction system FEC (Fume Extraction Cyclone) that removes harmful welding fumes from the welder zone in the most powerful and efficient way possible. FEC is the most evolved single torch fume extraction system available, using cyclone technology for particle pre-separation to protect the filter surface to reduce filter cleanings. The filter itself an integrated, permanent filtration concept that is easily and quickly cleaned – a Maintenance Manager’s dream. Disposal of welding dust is performed with the encapsulated de-dusting system and bag for a health-conscious and environmentally-friendly waste removal process. The thick plastic walls are quieter than other fume extraction units and, weighing at 25 kg with a full cushion wheel assembly, it is easily portable around the shop if needed.

Also on display will be the ABIMIG AT Air-cooled Manual MIG Torch, the most comfortable and versatile MIG torch of its kind. ABIMIG AT combines comfort and precision with a customizable solution at every step. With amperage ranged from 250 to 400, ABIMIG AT is the lightest MIG torch on the market. With easy to rotate, removable and varying torch neck designs, it can be custom-suited to any welding task the operator requires. These air-cooled torches use the revolutionary Bikox® cable for easy handling and low welder stress. ABIMIG AT has options everywhere: choose a standard or extended trigger, any torch neck length you need, and a slew of nozzle and contact tips consumable profiles for superior joint access and weldability.

Also on display will be ABIROB® Cyclone™ air-cooled robotic torches that use “endless rotation” technology to allow the torch neck to rotate 360 deg completely independent of the welding cable. This means programmers no longer need to worry about the torsional limits of the dreaded axis-6. Reduce cycle time? Check. Increase cable life? Check. Optimize welding efficiency? Check. Such programming freedom means reduced cycle times, higher outputs, and more on the bottom line for your manufacturing production. ABIROB Cyclone comes air-cooled up to 500 amps with torch neck angles at 22 deg and 45 deg.

Abicor Binzel USA, Inc., 650 Medimmune Court, Suite 110, Frederick, MD 21703-2602, 301-846-4196, www.binzel-abicor.com.