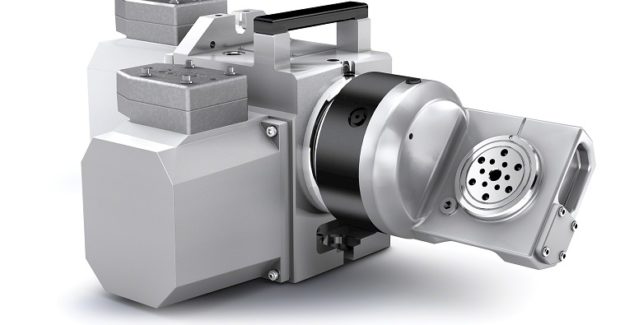

High Speed, Ultra-Compact, Dual-Axis Rotary Table for Machining Small Complex Medical Parts

The TRT70 dual-axis rotary table from Haas easily fits the smallest machining center or mounts on one end of a larger machine’s table, freeing up the remainder for additional fixtures or vises.

Posted: November 6, 2018

The TRT70 dual-axis rotary table from Haas Automation, Inc. (Oxnard, CA) delivers high speed and accurate positioning for 3+2 and full 5-axis machining of small, complex medical parts. The unit’s ultra-compact size and light weight make the TRT70 the perfect dual-axis solution for even the smallest machining center. The TRT70 uses powerful brushless servomotors to provide 60 ft-lb (81.3 Nm) of torque on the tilt axis and 40 ft-lb (54.2 Nm) on the rotary axis; indexing speeds of 410 deg/sec on the tilt axis and 620 deg/sec on the rotary axis ensure short cycle times. The unit provides ±120 deg of tilt and 360 deg of rotation to position parts to almost any angle for machining. The precision-ground 70 mm (2.76 in) platter features multiple bolt patterns and a precision through-bore for versatile fixturing. It will swing parts up to 4.0 in (102 mm) diameter. The maximum platter capacity is 3 lb (1.4 kg).

At just 18.5 in (470 mm) wide and 10 in (254 mm) deep, the TRT70 easily fits into even the smallest machining center or can be mounted on one end of a larger machine’s table, freeing up the remainder for additional fixtures or vises. It is the perfect complement for the new CM-1 Compact Mill or existing OM-Series Office Mills. The TRT70 can easily be removed when not needed. It is built in the U.S. and is backed by a worldwide network of Haas Factory Outlets for support and service.

Haas Automation, Inc., 2800 Sturgis Road, Oxnard, CA 93030, 805-278-1800, Fax: 805-988-6918, www.haascnc.com.