Renishaw and Altair Collaborate

They are working to bring metal 3D printing into high volume production, particularly in automotive applications.

Posted: November 14, 2018

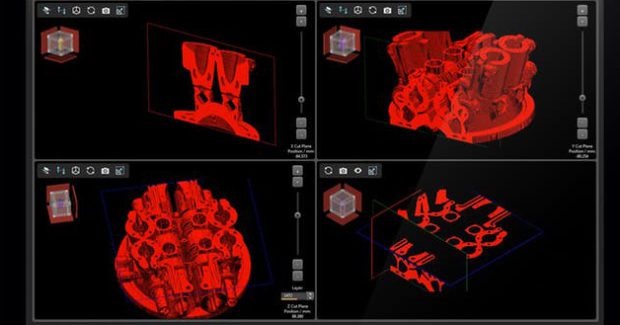

Renishaw Inc. (West Dundee, IL) has joined forces with Altair Engineering, Inc. (Troy, MI), a leading provider of enterprise-class engineering software, for a series of projects aimed at bringing additive manufacturing into serial end use production. “They are a world leader in simulation-driven design,” said Stephen Anderson, the AM business development manager of Renishaw. “Research combining their software with our latest systems will give them practical insights that will lead to innovative improvements in their products.” Altair’s simulation-driven innovative approach enables users to generate the highest quality, reliable designs with confidence that will print “right the first time.” Through their association, Renishaw has been able to leverage Altair’s full range of software products, such as the HyperWorks™ suite that includes Inspire™ and OptiStruct™.

“Working closely with them benefits the development and application of our software to optimize designs for functionality as well as for printability, accuracy and suitability for its designated purpose,” explained David Coates, a senior program manager at Altair. “This collaboration helps ensure AM part development, print cycles and scrap rates are minimized for our customers.” Altair has been able to rely on using Renishaw’s range of metal 3D printing systems to successfully manufacture products from customers’ concepts. They have worked closely together for many years, collaborating on multiple projects including working on a bike frame that is uniquely customized for every rider, a “spider” bracket for architectural glass panels and a pivoting bell crank for the suspension system of a race car.

Now the two teams are offering joint seminars, workshops and training events to customers that practically demonstrate metal AM production from powder to part, with emphasis placed on throughput and machine productivity. Customers can also engage in AM design projects with Altair to develop designs ideally suited for function and printability on the Renishaw series of printers. Similarly, customers wishing to use Renishaw Solutions Centers to design and test out the manufacturing of metal AM parts can rely on Altair software and expertise to help get the job done. “Together we are collaborating on customer-focused productivity projects, particularly in the automotive sector, which will lead to significant improvement in part volumes and lower costs per part,” noted Anderson.

“With their help, we are learning about how to best generate and simulate products for multiple laser systems and are actively thinking about laser assignment strategies within our simulation models,” added Coates.

www.renishaw.com, www.altair.com